Cookie Preferences

We use cookies to enhance your experience and analyze site usage.

By clicking "Accept All", you consent to the use of all cookies. Click "Customize" to choose which categories to enable, or "Reject All" to only use strictly necessary cookies. Learn more in our Cookie Policy

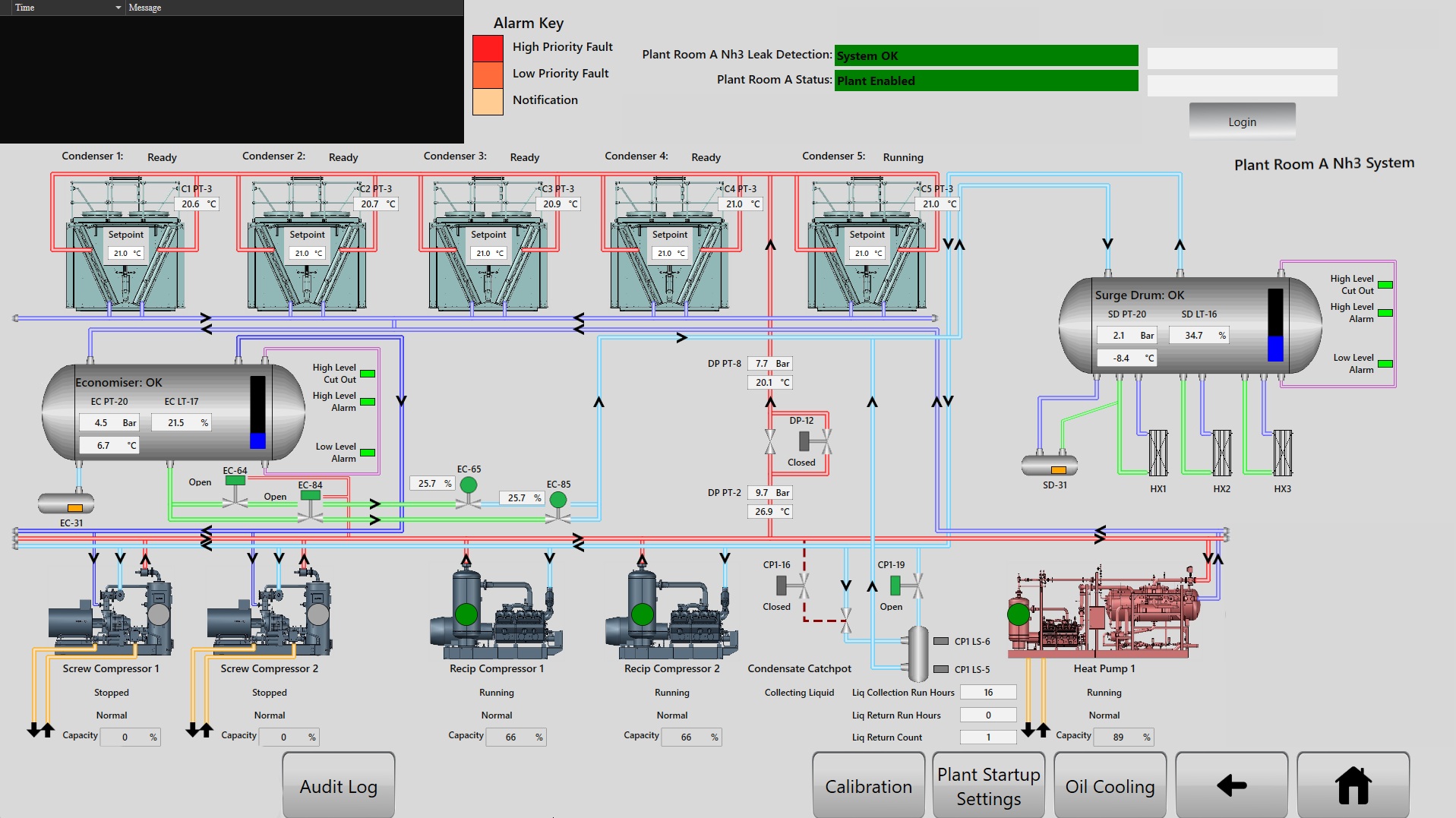

- Control Panels & MCC Design

Control Panel Design & Manufacture That Powers Reliable Operations

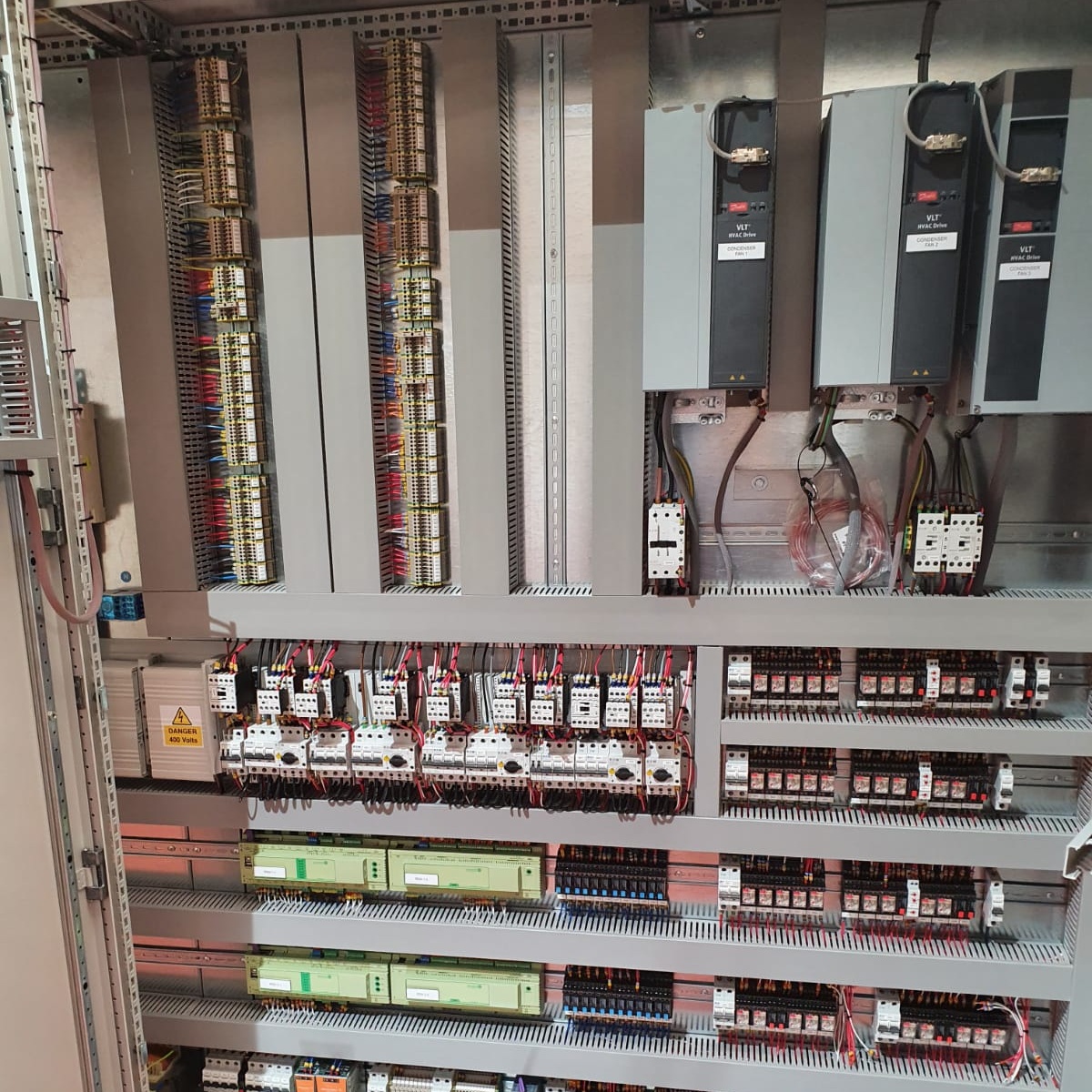

From basic single-phase to bespoke form 4 panels. We design and build custom control solutions for refrigeration, food processing, ventilation, and heating systems using the latest EPLAN software and BSEN60204-1 standards.

Trusted by UK manufacturers in food, building management systems, refrigeration & process engineering

Control Panels Built for Your Requirements

Every panel we design is custom-engineered to your exact specifications, ensuring optimal performance and compliance

Custom-Engineered

Tailored Solutions

Built to your exact specifications using advanced EPLAN software, ensuring every panel meets your unique operational requirements and space constraints.

Full Compliance

BSEN60204-1 Certified

Every panel is designed and manufactured to current BSEN60204-1 standards with complete electrical schematics and documentation for peace of mind.

Scalable Capacity

Basic single-Phase to bespoke 4 Form panels

From small single-phase panels to large Form 4 configurations we handle projects of any scale.

Whether you need a compact single-phase panel or a large multi-section Form 4 configuration, our team has the expertise and facilities to deliver exactly what your operation requires.

Discuss Your ProjectCustom Control Panel Excellence Since 1966

For over four decades, JBB has been designing and manufacturing control panels for the UK's most demanding industrial applications. From basic single-phase panels to bespoke form 4 configurations, we bring unmatched expertise to every project.

Design Engineering

Advanced EPLAN software and CAD capabilities ensure every panel is precisely engineered to your specifications with optimal layout and accessibility.

Quality Manufacturing

In-house manufacturing with rigorous quality control ensures every panel meets BSEN60204-1 standards and our exacting quality benchmarks.

Compliance Standards

Full compliance with current wiring regulations, complete with detailed electrical schematics and comprehensive documentation.

Field Support

From installation through commissioning and ongoing maintenance, we provide complete lifecycle support for every control panel we build.

Common Control Panel Challenges We Solve

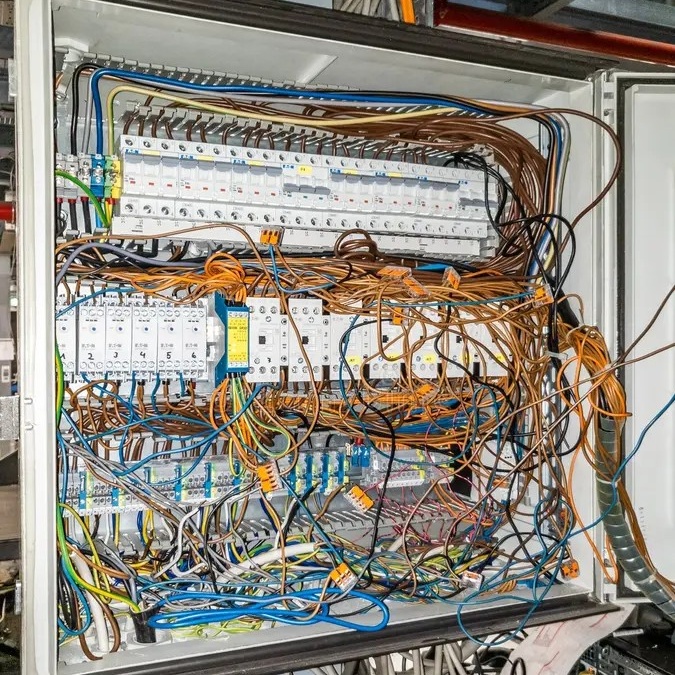

Outdated or poorly designed control panels create operational headaches that impact your business

Outdated Panel Designs

Panels that can't accommodate new equipment additions or modern monitoring systems, limiting your operational capabilities.

Poor Organization & Access

Badly organized panel layouts that restrict access and slow down maintenance, repairs, and troubleshooting.

Missing Documentation

Inadequate or outdated electrical drawings causing confusion during modifications and making compliance audits difficult.

Compliance Issues

Non-compliant panels failing safety inspections, creating legal risks and operational shutdowns.

Integration Limitations

Inability to integrate with modern SCADA, PLC, or temperature monitoring systems, leaving you with outdated control capabilities.

What's Included in Our Service

From initial consultation to ongoing support, we handle every aspect of your control panel project

Design Consultation

We analyze your system requirements, space constraints, and future expansion needs to create optimal panel specifications.

Custom Manufacturing

Using EPLAN software and quality components, we build panels in our facility to exact specifications with rigorous quality control.

Testing & Commissioning

Every panel undergoes comprehensive testing before and after installation to ensure safe, reliable operation.

Complete Documentation

You receive full electrical schematics, component lists, and maintenance guides for long-term system management.

Why Choose JBB for Control Panel Design & Manufacture

With over 40 years of experience, we deliver custom-engineered control panels that meet the highest standards of quality, compliance, and reliability.

40+ years designing panels for food manufacturing, pharmaceuticals, and industrial facilities

In-house manufacturing with EPLAN software for advanced PLC integration

NICEIC-approved installations backed by comprehensive warranties

Scalable solutions from small control panels to major distribution boards

Technical support available for when refrigeration systems fail and products are at risk.

Our Control Panel Design Process

A proven methodology that ensures quality, compliance, and reliable performance

Requirements Discovery

Understanding Your Needs

We conduct a detailed site assessment and gather your specifications, operational requirements, space constraints, and future expansion plans.

Design & Engineering

Custom Panel Design

Using SEE software, we create detailed CAD drawings, select optimal components, and design panel layouts that maximize efficiency and accessibility.

Manufacturing & Testing

Quality-Controlled Build

Our in-house team manufactures your panel to exacting standards, then performs comprehensive factory acceptance testing before delivery.

Installation & Handover

Commission & Support

We install and commission your panel on-site, provide full documentation and training, and remain available for ongoing support and maintenance.

Services That Work Well With Control Panels

PLC & Software Development

Expert PLC programming and software solutions for automated control systems. We develop custom control logic, SCADA interfaces, and integration solutions that optimise your processes and improve operational efficiency.

Learn MorePreventive Electrical Maintenance

Planned preventative maintenance programmes designed to maximise equipment reliability and minimise unexpected downtime. Our proactive approach keeps your electrical systems operating at peak performance.

Learn MoreTesting & Certification

Comprehensive testing and certification services ensuring compliance and safety. From fixed wiring inspections to PAT testing, we provide thorough assessments and the documentation you need for regulatory compliance.

Learn MoreWhat Our Clients Say

Trusted by operations and engineering leaders across the UK

"I have worked with the team at JBB Electrical on a wide range of projects and reactive works for over 15 years. They consistently complete jobs to an excellent standard and are always a pleasure to deal with. Their technical knowledge is a huge benefit to both myself and my customers, and nothing is ever too much trouble for the team. They regularly go above and beyond, and I would not hesitate to recommend JBB Electrical"

Ian Ross

Service Manager, EJM

"The team at JBB Electrical have been integral to the implementation of the proof-of-concept large scale energy‑sharing district heating & cooling network at SmartParc’s food production campus in Derby. JBB’s wealth of knowledge and experience in industrial controls and automation helped integrate the multiple systems and platforms required for seamless control and monitoring of the energy centre plant and park network. JBB have also secured and successfully delivered the electrical subcontract works associated with the industrial cooling installations for all tenants on the park thus far. All under competitive tender and ambitious installation programmes. All projects have been completed on time, within budget and to the highest quality standards. I can highly recommend JBB as partner of choice for complex industrial electrical and automation projects."

Mike Roberts

Senior Technical Manager, SmartParc

Frequently Asked Questions

Find answers to common questions about our electrical installation services

Explore Our Resources

Why Industrial Circuit Breakers Trip in Industrial Systems

Developing a Critical Spares Strategy for Industrial Facilities