Cookie Preferences

We use cookies to enhance your experience and analyze site usage.

By clicking "Accept All", you consent to the use of all cookies. Click "Customize" to choose which categories to enable, or "Reject All" to only use strictly necessary cookies. Learn more in our Cookie Policy

- Critical Spares

Critical Spares Strategy & Component Supply That Protects Your Production

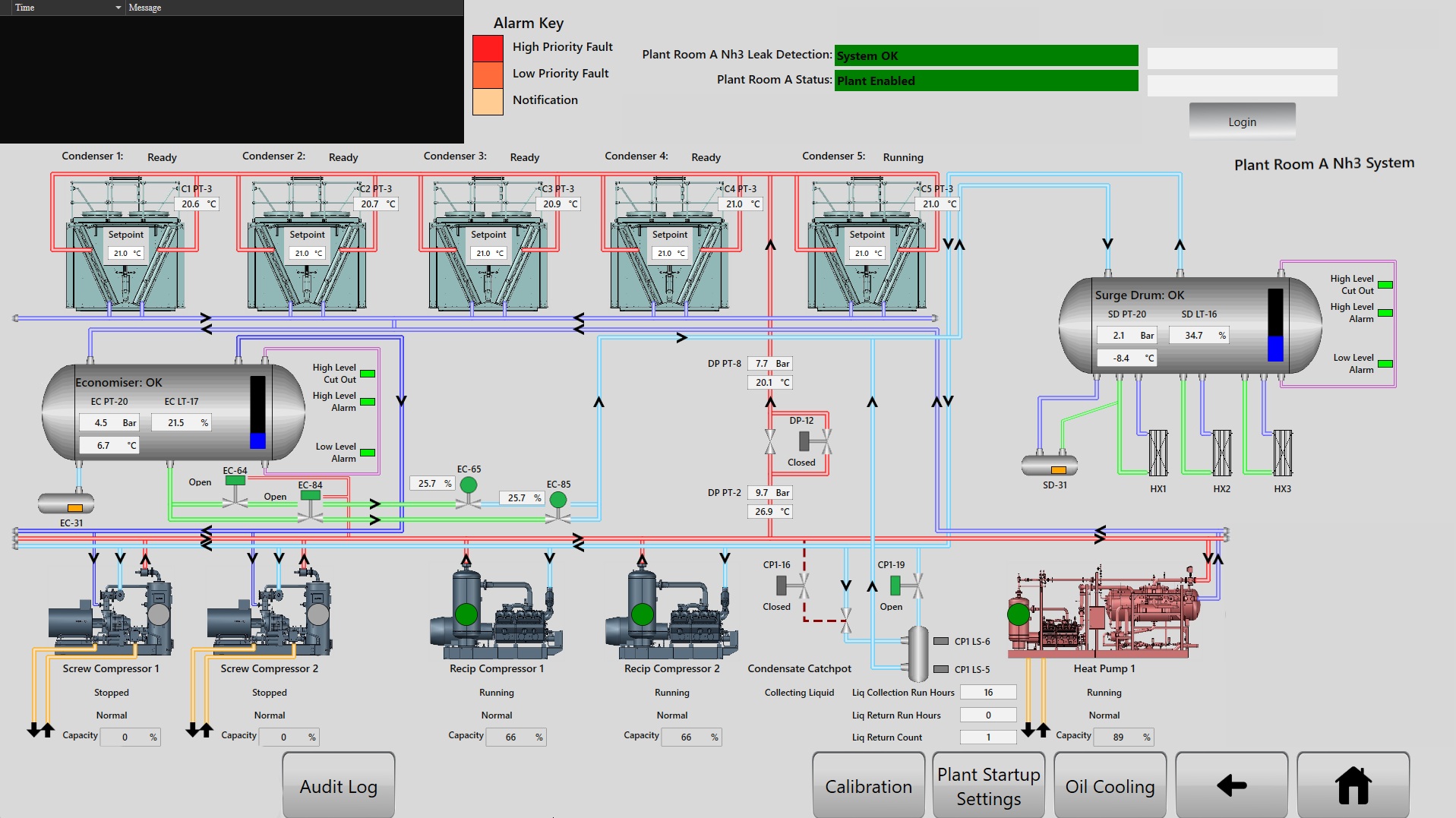

From PLC modules to safety components and industrial network devices. We identify, classify, and supply essential spares that eliminate catastrophic downtime and keep your temperature-critical operations running.

Trusted by UK manufacturers in food, building management systems, refrigeration & process engineering

Proactive Strategy

Risk-Based Assessment

We audit your control systems to identify single points of failure and classify components by criticality, lead time, and obsolescence risk.

Obsolescence Protection

Future-Proof Your Systems

Strategic spares planning for aging equipment and end of life components, protecting against forced upgrades during critical failures.

Technical Excellence

Trusted guidance on PLC and panel spares

We provide technically informed advice on critical PLC and control panel spares to ensure system compatibility, resilience, and minimised downtime.

Whether you need basic spares strategy for a single production line or comprehensive component management across multiple sites, our team has the expertise and supply channels to deliver exactly what your operation requires.

Discuss Your RequirementsCritical Spares Management for Industrial Control Systems

For over four decades, JBB has been protecting UK manufacturers and temperature-critical facilities from preventable downtime through strategic component management. From basic control panels to complex control systems, we bring systematic risk assessment and practical spares planning to every operation.

Risk-Based Analysis

Comprehensive audit of your control panels identifying single points of failure, component lead times, and obsolescence risks with prioritized spares recommendations.

Rapid Availability

Supply of genuine PLC modules, I/O cards, HMIs, safety relays, network devices, and power supplies ensuring critical components are available when failures occur.

Documentation Protection

Complete backup of PLC programs, HMI configurations, and electrical schematics with secure storage and documented replacement procedures for your maintenance teams.

Obsolescence Management

Forward-looking assessment of aging equipment and end-of-life components, protecting against scenarios where failures force unplanned system replacements or extended outages.

Common Critical Spares Challenges We Solve

Without a structured spares strategy, component failures create operational headaches that impact your business

Long OEM Lead Times

PLC modules, CPUs, and specialist components often have 6-10 week delivery times, turning minor component failures into extended production shutdowns.

Obsolete Components

Aging control systems using end-of-life PLC series face impossible replacement scenarios when critical modules fail without readily available alternatives.

Unidentified Failure Risks

Lack of systematic assessment means facilities don't know which component failures will cause complete production loss versus minor disruption.

Missing Program Backups

Inadequate or outdated PLC program archives causing extended recovery times during component replacement and making simple fixes unnecessarily complex.

Uncontrolled Costs

Stocking every possible spare is financially unrealistic, but failing to stock critical components costs far more in emergency downtime and rush shipping.

What's Included in Our Critical Spares Service

From initial assessment to ongoing supply management, we handle every aspect of your critical spares strategy

Critical Spares Audit

We analyse your control panels, document all components, and assess failure risks to identify which parts pose the greatest threat to your operation.

Risk Classification

Each component is evaluated for failure impact, lead time exposure, and obsolescence status to create a prioritised spares matrix with cost-benefit analysis.

Component Supply

We source and supply genuine PLC modules, I/O cards, HMIs, safety components, and network devices from authorised distributors with full traceability.

Program Backup & Documentation

You receive complete PLC program backups, HMI configurations, electrical schematics, and documented replacement procedures for rapid restoration.

Why Choose JBB for Critical Spares Strategy

With over 40 years of industrial control experience, we deliver risk-based spares strategies that protect your operation from preventable downtime.

40+ years managing control systems for food manufacturing, pharmaceuticals, and temperature-critical facilities

Multi-platform expertise across Siemens, Allen-Bradley, Mitsubishi, Schneider, and legacy PLC systems

Authorised supply channels ensuring genuine components with full traceability and warranty protection

Risk-based methodology prioritising components by actual downtime impact and financial exposure

Breakdown support available for when critical failures occur and rapid component replacement is needed

Our Critical Spares Assessment Process

Proven procedures that minimize downtime and restore operations safely

System Audit & Documentation

Understanding Your Infrastructure

We conduct a comprehensive site assessment and document all control panels, PLCs, I/O modules, HMIs, safety components, and network devices across your facility.

Risk Classification & Analysis

Identifying Critical Components

Each component is assessed for failure impact, lead time exposure, obsolescence risk, and replacement complexity to create a prioritised spares matrix.

Spares Strategy Development

Building Your Protection Plan

We develop recommended inventory based on risk tolerance, budget constraints, and operational requirements with clear cost-benefit analysis for each component.

Supply & Implementation

Component Delivery & Support

We supply recommended components, create storage and labeling systems, backup all programs and configurations, and document replacement procedures for your teams.

Services That Complement Emergency Response

Testing & Certification

Comprehensive testing and certification services ensuring compliance and safety. From fixed wiring inspections to PAT testing, we provide thorough assessments and the documentation you need for regulatory compliance.

Learn MorePreventive Electrical Maintenance

Planned preventative maintenance programmes designed to maximise equipment reliability and minimise unexpected downtime. Our proactive approach keeps your electrical systems operating at peak performance.

Learn MoreControl Panels & MCC Design

Professional control panel design and manufacturing services for industrial and commercial applications. From concept to commissioning, we deliver bespoke solutions that meet your exact specifications and comply with all relevant standards.

Learn MoreWhat Our Clients Say

Trusted by operations and engineering leaders across the UK

"I have worked with the team at JBB Electrical on a wide range of projects and reactive works for over 15 years. They consistently complete jobs to an excellent standard and are always a pleasure to deal with. Their technical knowledge is a huge benefit to both myself and my customers, and nothing is ever too much trouble for the team. They regularly go above and beyond, and I would not hesitate to recommend JBB Electrical"

Ian Ross

Service Manager, EJM

"The team at JBB Electrical have been integral to the implementation of the proof-of-concept large scale energy‑sharing district heating & cooling network at SmartParc’s food production campus in Derby. JBB’s wealth of knowledge and experience in industrial controls and automation helped integrate the multiple systems and platforms required for seamless control and monitoring of the energy centre plant and park network. JBB have also secured and successfully delivered the electrical subcontract works associated with the industrial cooling installations for all tenants on the park thus far. All under competitive tender and ambitious installation programmes. All projects have been completed on time, within budget and to the highest quality standards. I can highly recommend JBB as partner of choice for complex industrial electrical and automation projects."

Mike Roberts

Senior Technical Manager, SmartParc

Frequently Asked Questions

Find answers to common questions about our emergency response services

Why Industrial Circuit Breakers Trip in Industrial Systems

Developing a Critical Spares Strategy for Industrial Facilities