Cookie Preferences

We use cookies to enhance your experience and analyze site usage.

By clicking "Accept All", you consent to the use of all cookies. Click "Customize" to choose which categories to enable, or "Reject All" to only use strictly necessary cookies. Learn more in our Cookie Policy

- Preventive Electrical Maintenance

Preventive Maintenance That Keeps Production Running

Scheduled maintenance programmes that prevent breakdowns, extend equipment life, and protect your operations from costly unplanned downtime.

Trusted by UK manufacturers in food, building management systems, refrigeration & process engineering

Maintenance Programmes That Protect Your Investment

Reduce breakdowns with scheduled preventive maintenance

Prevent Failures

Before They Happen

Identify and address potential issues before they cause breakdowns, protecting your operations from unexpected downtime and emergency callout costs.

Extend Equipment Life

Maximise Asset Value

Regular maintenance extends the operational lifespan of your electrical systems, delaying expensive replacement costs and maximising your capital investment.

Planned Servicing

On Your Schedule

Scheduled maintenance during planned shutdowns means no surprise disruptions to your production schedule or peak operating periods.

-cropped-1768825096317.jpg)

From annual contracts to one-off inspections, our maintenance programmes keep your electrical systems reliable and your operations running smoothly.

Discuss Your ProjectComprehensive Preventive Maintenance Expertise

For over 40 years, we've been helping UK manufacturers avoid costly breakdowns through systematic preventive maintenance. Our programmes cover everything from routine inspections to thermal imaging surveys and detailed testing protocols.

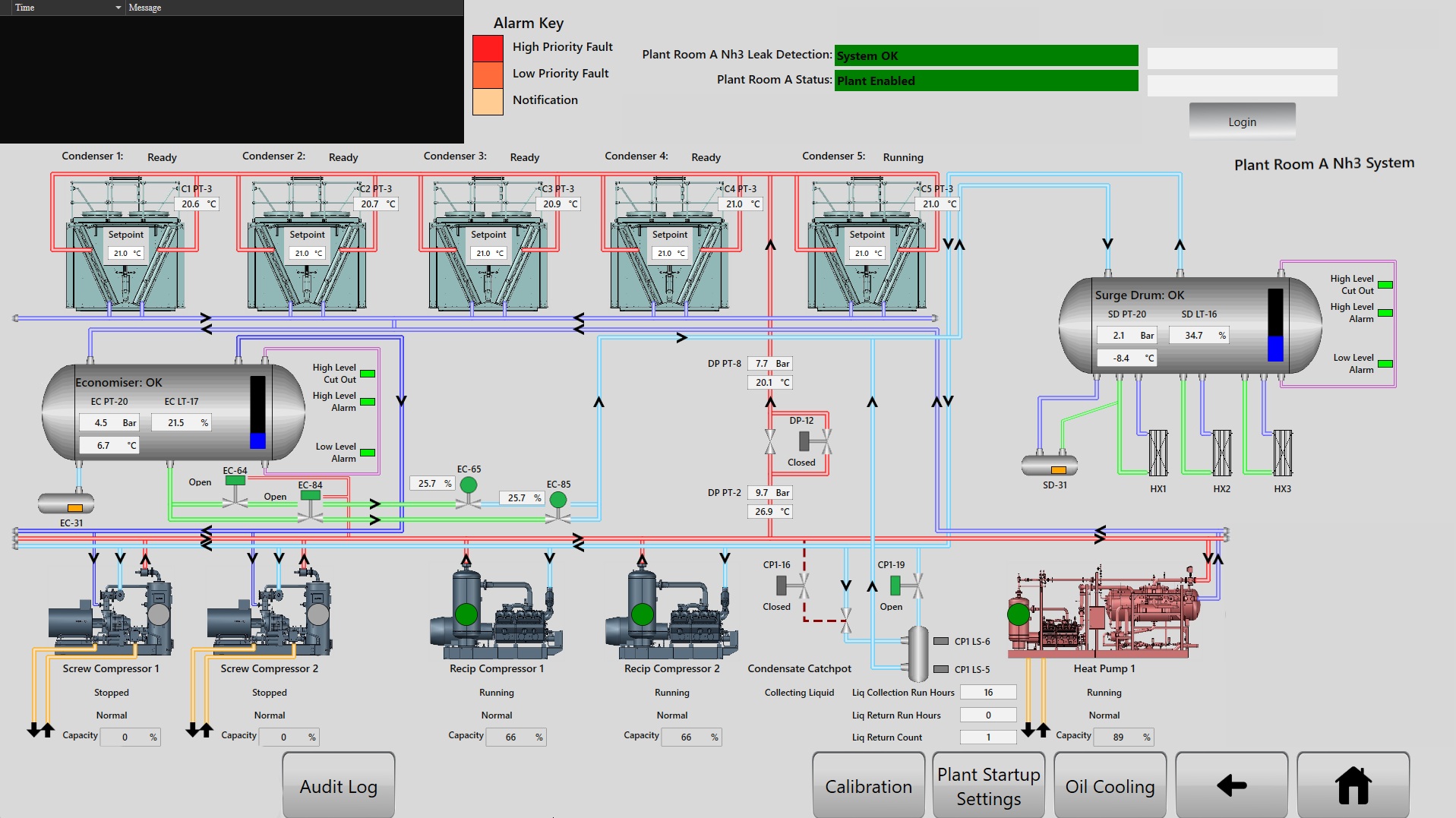

Electrical Testing

Regular inspection and testing of control panels, distribution boards, motors, and critical electrical infrastructure to BSEN60204-1 standards.

Thermal Imaging

Advanced infrared surveys detect hot spots, loose connections, and failing components before they cause failures or fire hazards.

Scheduled Inspections

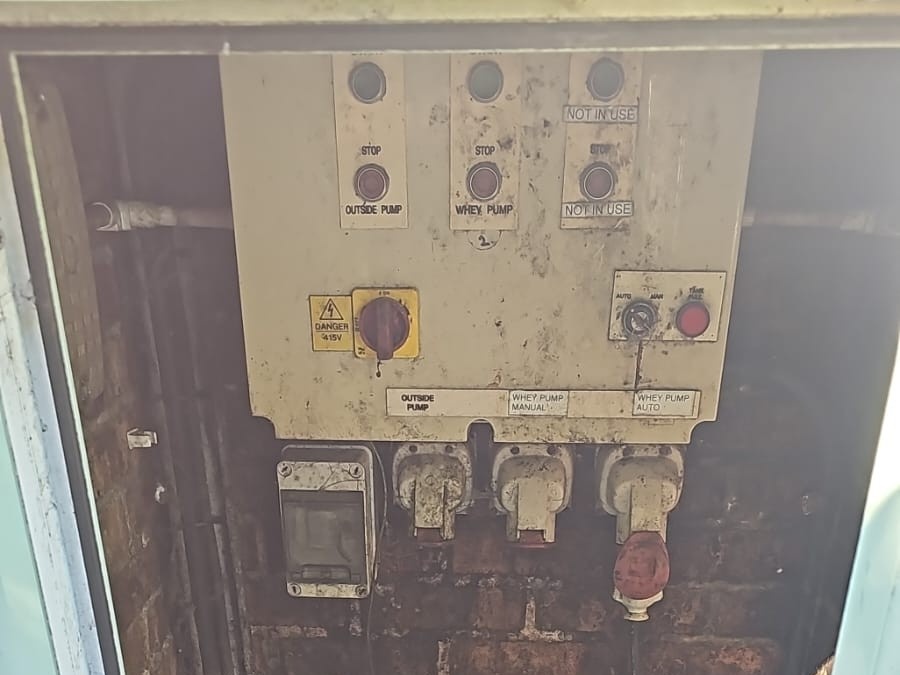

Comprehensive visual inspections, connection tightening, cleaning, and adjustment during planned production shutdowns.

Maintenance Records

Detailed service reports, test results, and photographic evidence create a complete maintenance history for compliance audits.

The True Cost of Reactive Maintenance

Equipment failures rarely announce themselves in advance. When electrical systems fail unexpectedly, the consequences cascade through your operation—production stops, emergency callout fees mount, related equipment gets damaged, and your team scrambles under pressure to restore operations.

Emergency Callout Costs

Out-of-hours emergency repairs cost significantly more than scheduled maintenance visits, with premium rates for urgent response and parts.

Production Downtime

Unplanned stoppages disrupt production schedules, delay customer orders, and create rushed recovery situations that compound stress and costs.

Cascading Failures

One failing component often damages related equipment, turning a simple repair into a major system rebuild with extended downtime.

Safety Incidents

Poorly maintained electrical systems increase risks of shock hazards, arc flash incidents, and fire dangers that threaten personnel and facilities.

Premature Replacements

Equipment that isn't properly maintained fails earlier than its design life, forcing expensive replacements years before necessary.

What's Included in Our Maintenance Programmes

Comprehensive servicing that covers all aspects of your electrical systems

Visual Inspections

Detailed examination of control panels, connections, cables, and equipment for signs of wear, damage, overheating, or deterioration.

Electrical Testing

Insulation resistance, earth continuity, and visual inspection tests verify safe operation and identify developing faults before they fail.

Thermal Imaging

Infrared surveys detect hot spots, loose connections, and overloaded circuits that aren't visible to the naked eye.

Service Reports

Comprehensive documentation including photographs, test results, defect lists, and prioritised recommendations for remedial works.

Why Choose JBB for Preventive Maintenance

With Scheduled preventative maintenance, your electrical infrastructure becomes predictable, reliable and safe. Our Systematic approach catches small issues before they become expensive emergencies, keeping your operations running smoothly year after year.

Industry Experience: 40+ years calibrating temperature systems for food manufacturing, pharmaceuticals, and cold storage facilities

Traceable Standards: UKAS-traceable reference standards ensuring measurement accuracy aligned with national and international requirements

Regulatory Expertise: Experience across HACCP, GDP, GMP, ISO 9001, and industry-specific regulatory frameworks

Temperature Mapping: Complete temperature mapping services identifying hot and cold spots for optimal monitoring system design

Ongoing Management Ongoing calibration management including scheduling, documentation, and compliance record maintenance

Our Maintenance Process

A structured approach that fits around your operations

Schedule & Planning

Convenient Timing

We work with your production schedule to arrange maintenance visits during planned shutdowns or quiet periods, minimising operational impact.

Inspection & Testing

Comprehensive Checks

Our engineers conduct visual inspections, electrical tests, thermal imaging surveys, and connection checks across all your electrical systems.

Servicing & Adjustments

Preventive Actions

We clean, tighten, adjust, and service equipment, addressing minor issues immediately and preventing them from developing into major problems.

Reporting & Recommendations

Clear Documentation

You receive detailed reports with photographs, test results, and prioritised recommendations for any remedial works or upgrades needed.

Related Services

Testing & Certification

Comprehensive testing and certification services ensuring compliance and safety. From fixed wiring inspections to PAT testing, we provide thorough assessments and the documentation you need for regulatory compliance.

Learn MoreElectrical Installations & Design

Professional electrical installation services from initial planning through to final certification. Our experienced team delivers safe, compliant installations for industrial, commercial, and food production environments.

Learn MoreControl Panels & MCC Design

Professional control panel design and manufacturing services for industrial and commercial applications. From concept to commissioning, we deliver bespoke solutions that meet your exact specifications and comply with all relevant standards.

Learn MoreWhat Our Clients Say

Trusted by operations and engineering leaders across the UK

"I have worked with the team at JBB Electrical on a wide range of projects and reactive works for over 15 years. They consistently complete jobs to an excellent standard and are always a pleasure to deal with. Their technical knowledge is a huge benefit to both myself and my customers, and nothing is ever too much trouble for the team. They regularly go above and beyond, and I would not hesitate to recommend JBB Electrical"

Ian Ross

Service Manager, EJM

"The team at JBB Electrical have been integral to the implementation of the proof-of-concept large scale energy‑sharing district heating & cooling network at SmartParc’s food production campus in Derby. JBB’s wealth of knowledge and experience in industrial controls and automation helped integrate the multiple systems and platforms required for seamless control and monitoring of the energy centre plant and park network. JBB have also secured and successfully delivered the electrical subcontract works associated with the industrial cooling installations for all tenants on the park thus far. All under competitive tender and ambitious installation programmes. All projects have been completed on time, within budget and to the highest quality standards. I can highly recommend JBB as partner of choice for complex industrial electrical and automation projects."

Mike Roberts

Senior Technical Manager, SmartParc

Frequently Asked Questions

Find answers to common questions about our electrical installation services

Explore Our Resources

Stay up-to-date with the latest in technology, regulation and insights. Discover expert guidance, industry updates, and practical advice to keep your operations safe, compliant, and optimised.

Why Industrial Circuit Breakers Trip in Industrial Systems

Developing a Critical Spares Strategy for Industrial Facilities