Cookie Preferences

We use cookies to enhance your experience and analyze site usage.

By clicking "Accept All", you consent to the use of all cookies. Click "Customize" to choose which categories to enable, or "Reject All" to only use strictly necessary cookies. Learn more in our Cookie Policy

- Refrigeration Control Systems

Refrigeration Plant Control & Wiring Specialists

Expert electrical design, installation, and control systems for industrial and commercial refrigeration plants. From cold storage to food processing, we ensure reliable temperature control and efficient operation.

Trusted by UK manufacturers in food, building management systems, refrigeration & process engineering

Specialised Refrigeration Expertise

Decades of experience delivering reliable temperature control systems

Refrigeration Specialists

Industry Experts

Decades of experience with cold storage, blast freezers, and process cooling systems for food and pharmaceutical applications.

Precise Control

Reliable Operation

Custom control systems that maintain exact temperatures and optimise energy efficiency whilst ensuring product safety.

Complete Service

Design to Maintenance

From initial electrical design and wiring through control programming, commissioning, and ongoing support.

When product safety and quality depend on reliable refrigeration, you need electrical contractors who understand the unique demands of temperature-critical operations.

Discuss Your ProjectSpecialised Refrigeration Control Engineering

Refrigeration systems demand specialised electrical expertise. For over four decades, we've been designing control systems, wiring plants, and maintaining critical cold storage infrastructure for food processors, cold storage facilities, and industrial refrigeration applications across the UK.

Refrigeration Systems

Expert electrical design and wiring for blast freezers, cold storage rooms, process cooling, and complex multi-zone refrigeration plants.

Temperature Control

Precise control systems that maintain exact temperatures, integrate with monitoring systems, and optimise energy efficiency.

Alarm Systems

Critical temperature alarm systems with SMS and email alerts to protect your products from temperature excursions and equipment failures.

Regulatory Compliance

Complete electrical compliance for food safety regulations and requirements for temperature logging and audit trails.

The Critical Risks of Refrigeration System Failures

Temperature control failures can destroy products and entire businesses overnight

Product Spoilage

Temperature excursions can destroy entire cold stores of product, resulting in hundreds of thousands in write-offs and lost revenue.

Food Safety Compliance

Failure to maintain proper temperatures and records can result in FSA enforcement, product recalls, and prosecution under food safety law.

System Inefficiency

Poorly designed or maintained refrigeration systems waste enormous amounts of energy, creating high running costs and environmental impact.

Inadequate Monitoring

Without proper alarm systems and temperature logging, problems go undetected until products are already damaged and compliance is compromised.

What's Included in Refrigeration Control Services

Complete electrical solutions for temperature-critical operations

Electrical Design

Complete electrical design for refrigeration installations including load calculations, cable sizing, and control panel specifications.

Installation & Wiring

Professional installation of control panels, containment systems, wiring and electrical infrastructure, for power, control and monitoring of refrigeration systems.

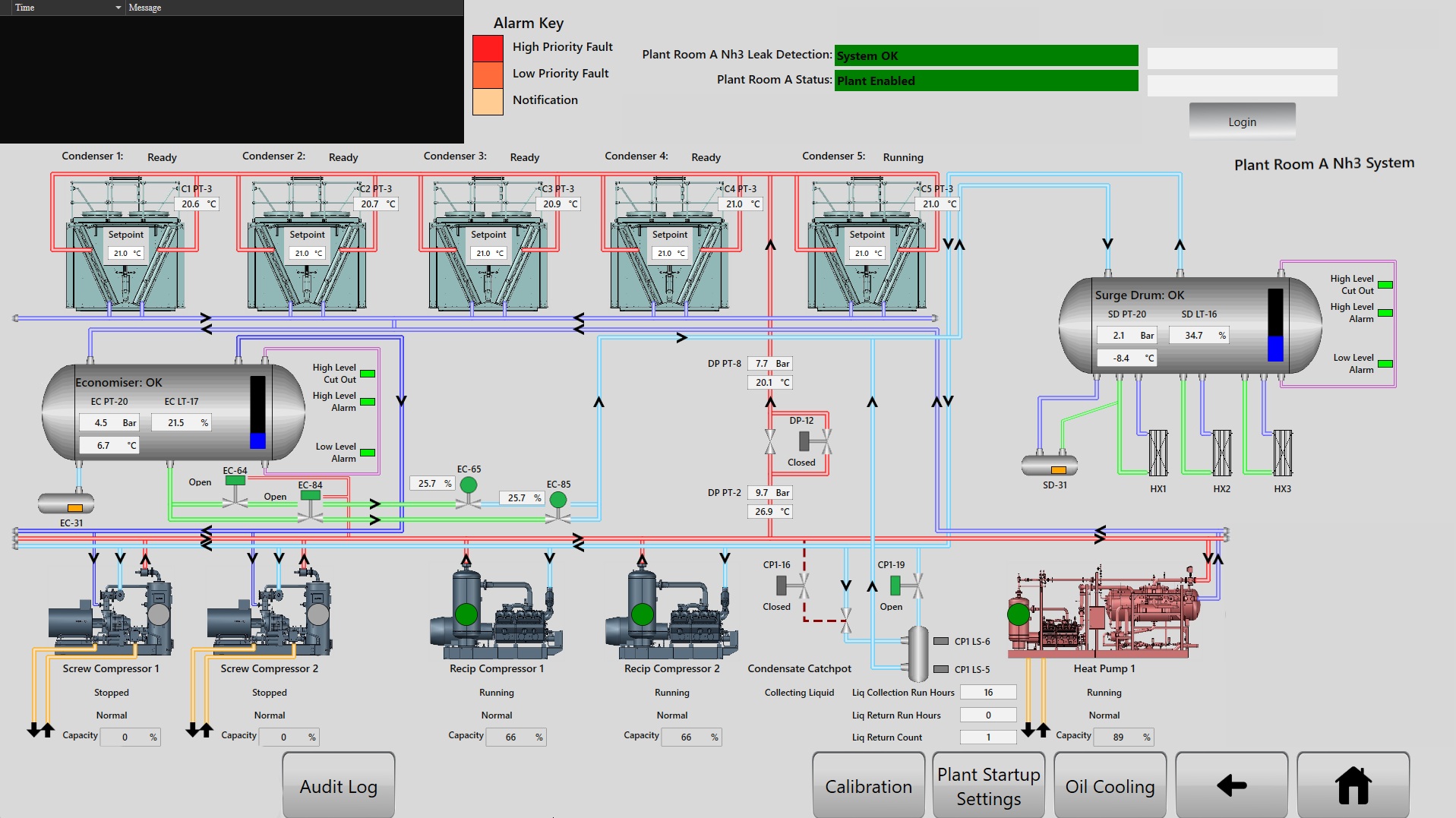

Control Systems

Custom PLC control and software programming for precise temperature regulation, energy optimisation, and integration with monitoring systems.

Monitoring & Alarms

Temperature monitoring systems with SMS/email alerts, data logging, and compliance reporting for food safety regulations.

Why Choose JBB for Refrigeration Control

Over 40 years of specialised expertise in refrigeration electrical systems for temperature-critical operations.

Over 40 years specialising in refrigeration electrical control systems for food and pharmaceutical industries

Custom control systems designed for energy efficiency and reliable operation

Complete service from design through installation, commissioning, and ongoing maintenance

Technical support available when refrigeration systems fail and products are at risk

Our Refrigeration Control Process

Systematic approach to delivering reliable temperature control

Requirements Analysis

Understand Your Needs

We analyse your refrigeration requirements including temperatures, zones, electrical requirements and compliance needs to design the optimal system.

Design & Engineering

Custom Solutions

Our engineers create detailed electrical designs, control schematics and panel layouts tailored to your specific application.

Installation & Programming

Professional Implementation

We install all electrical infrastructure, build custom control panels, program plc control systems and integrate temperature monitoring with thorough testing at every stage.

Commissioning & Support

Ongoing Reliability

Complete system commissioning with operator training, documentation and ongoing maintenance support to ensure continued reliability.

Related Services

Temperature Monitoring

Comprehensive temperature monitoring systems for compliance and quality control. Our solutions provide continuous data logging, real-time alerts, and detailed reporting to meet HACCP and regulatory requirements.

Learn MorePreventive Electrical Maintenance

Planned preventative maintenance programmes designed to maximise equipment reliability and minimise unexpected downtime. Our proactive approach keeps your electrical systems operating at peak performance.

Learn MorePLC & Software Development

Expert PLC programming and software solutions for automated control systems. We develop custom control logic, SCADA interfaces, and integration solutions that optimise your processes and improve operational efficiency.

Learn MoreWhat Our Clients Say

Trusted by operations and engineering leaders across the UK

"I have worked with the team at JBB Electrical on a wide range of projects and reactive works for over 15 years. They consistently complete jobs to an excellent standard and are always a pleasure to deal with. Their technical knowledge is a huge benefit to both myself and my customers, and nothing is ever too much trouble for the team. They regularly go above and beyond, and I would not hesitate to recommend JBB Electrical"

Ian Ross

Service Manager, EJM

"The team at JBB Electrical have been integral to the implementation of the proof-of-concept large scale energy‑sharing district heating & cooling network at SmartParc’s food production campus in Derby. JBB’s wealth of knowledge and experience in industrial controls and automation helped integrate the multiple systems and platforms required for seamless control and monitoring of the energy centre plant and park network. JBB have also secured and successfully delivered the electrical subcontract works associated with the industrial cooling installations for all tenants on the park thus far. All under competitive tender and ambitious installation programmes. All projects have been completed on time, within budget and to the highest quality standards. I can highly recommend JBB as partner of choice for complex industrial electrical and automation projects."

Mike Roberts

Senior Technical Manager, SmartParc

Frequently Asked Questions

Find answers to common questions about our electrical installation services

Explore Our Resources

Stay informed with our latest guides, insights, and technical articles on electrical installations and industrial systems.

Why Industrial Circuit Breakers Trip in Industrial Systems

Developing a Critical Spares Strategy for Industrial Facilities