Cookie Preferences

We use cookies to enhance your experience and analyze site usage.

By clicking "Accept All", you consent to the use of all cookies. Click "Customize" to choose which categories to enable, or "Reject All" to only use strictly necessary cookies. Learn more in our Cookie Policy

- PLC & Software Development

PLC Software & SCADA/HMI's That Bring Your Systems to Life

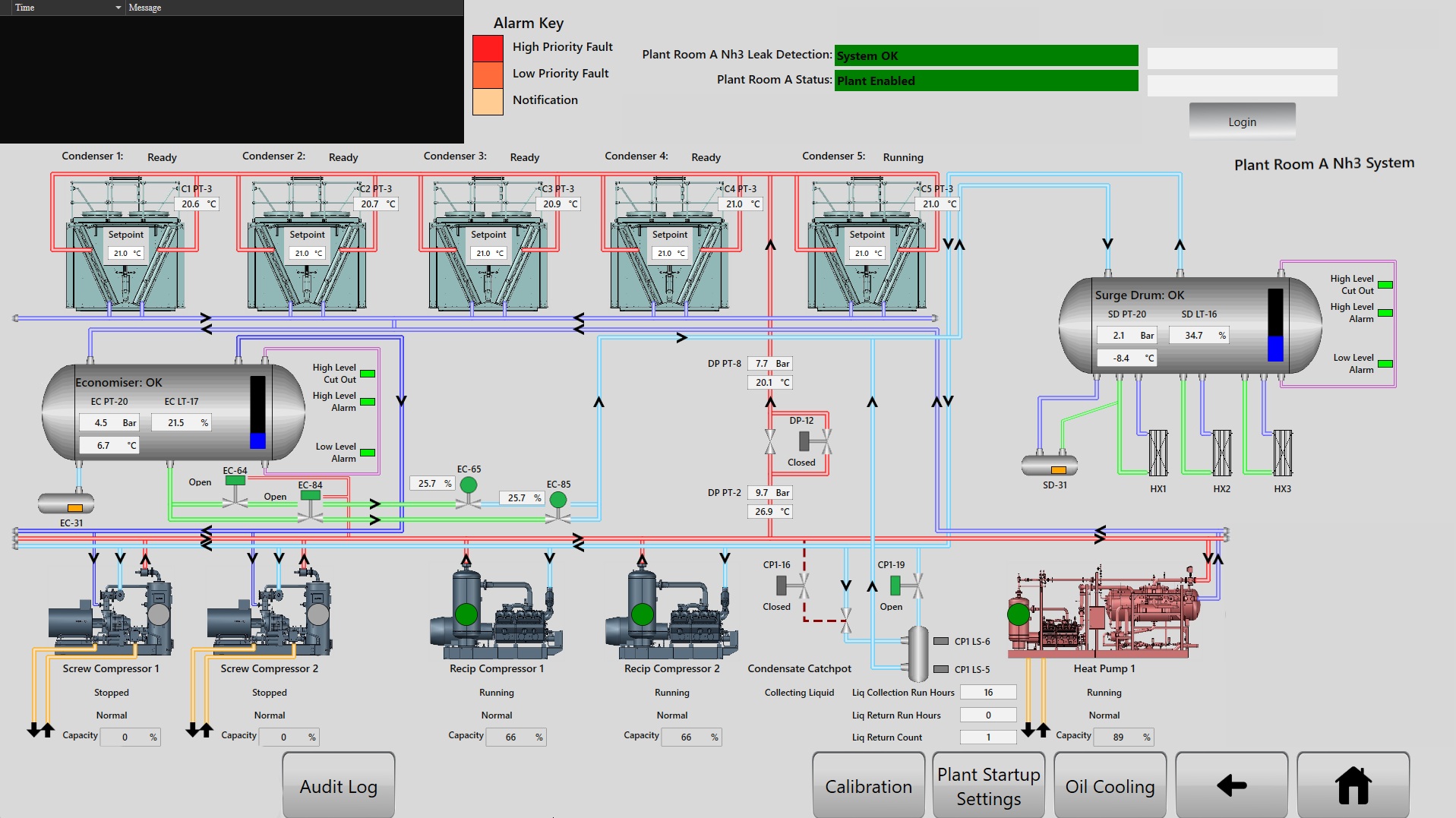

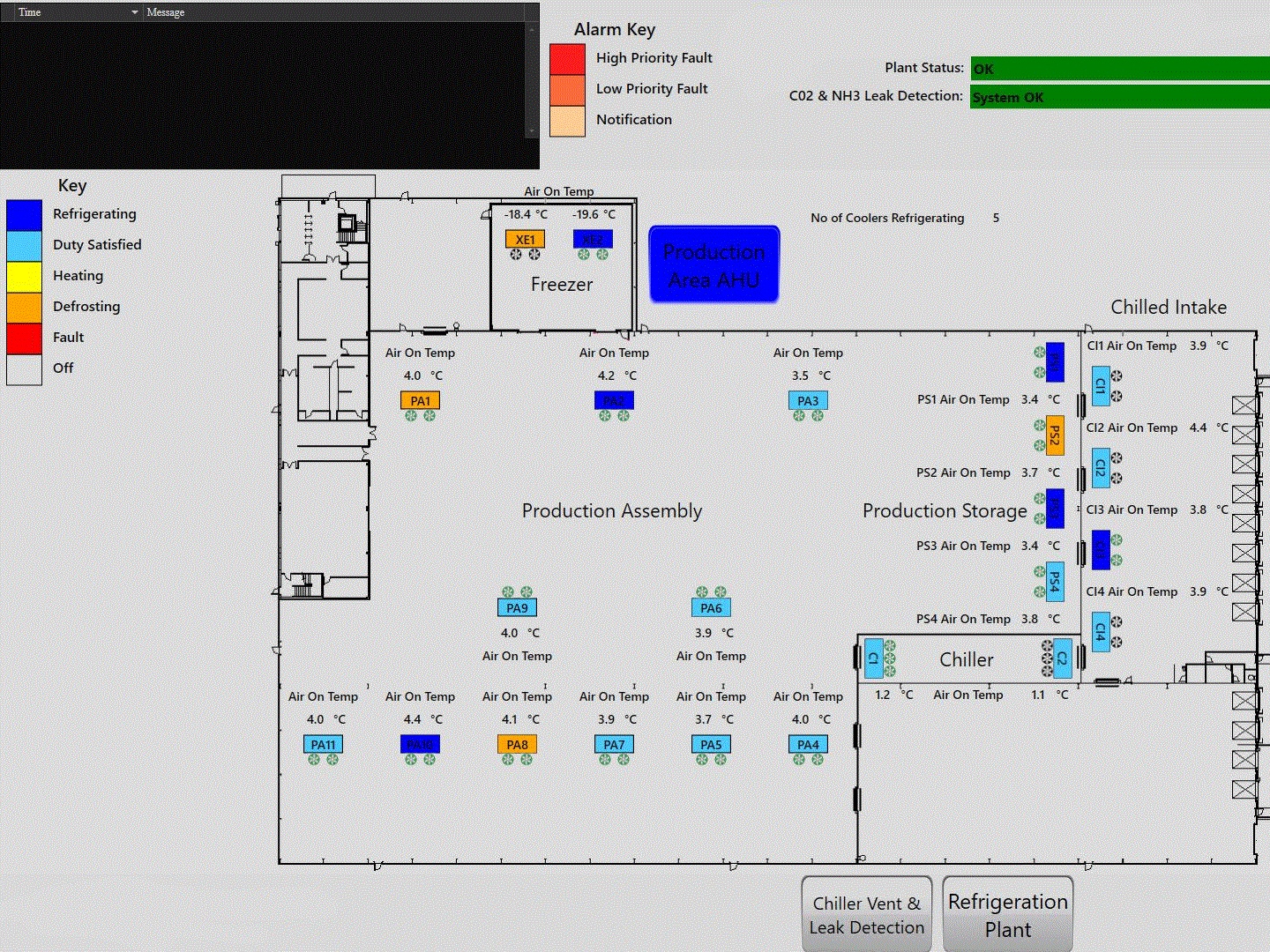

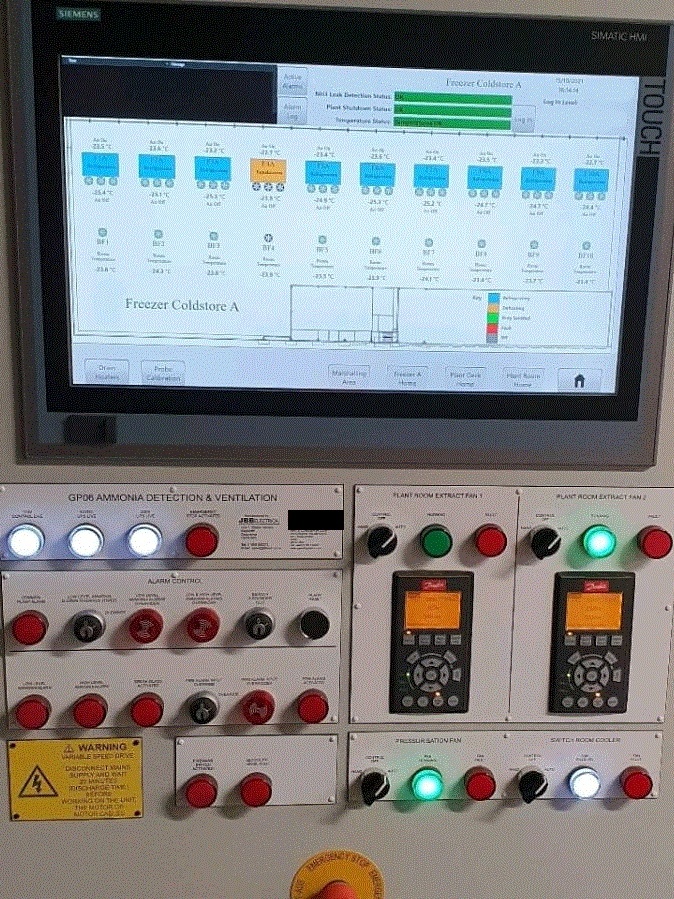

Custom PLC programming and HMI interface design for intelligent control and monitoring. From Siemens and Allen-Bradley to custom SCADA graphics, we create automation solutions that optimise your operations.

Trusted by UK manufacturers in food, building management systems, refrigeration & process engineering

Intelligent Automation for Modern Operations

Custom Programming

Tailored Logic

PLC programs designed specifically for your processes, equipment, and operational requirements.

Intuitive HMI Graphics

User-Friendly Interfaces

Clear, visual control interfaces that make complex systems easy to monitor and operate.

SCADA

Supervisory Control & Data Acquisition

Custom SCADA systems for monitoring and remote control of industrial processes in real time.

Industrial Automation Programming Across All Major Platforms

Our programming team brings decades of experience creating PLC software and HMI graphics for industrial automation. From Siemens and Allen-Bradley to Mitsubishi and custom SCADA systems, we develop control solutions that optimise your operations and enhance visibility.

PLC Programming

Expert ladder logic and function block programming tailored to your processes, from simple sequences to complex multi-zone control systems.

HMI Graphics

Intuitive visual interfaces that make complex systems easy to monitor and control, with clear alarms and real-time data visualization.

System Integration

Seamless integration of PLCs with BMS temperature monitoring, refrigeration controls, SCADA systems, and enterprise-level reporting.

Training & Documentation

Comprehensive operator training and complete program documentation ensure your team can maintain and modify systems confidently.

Common PLC & SCADA Challenges

Outdated or poorly documented automation systems create real operational risks and missed opportunities for efficiency.

Outdated Control Systems

Legacy PLC programs that cannot accommodate new equipment, modern sensors, or enhanced control requirements without complete rewrites.

Poor Visibility & Monitoring

Limited or non-existent system monitoring making it extremely difficult to identify problems, track performance, or optimise operations effectively.

Undocumented Code

PLC programs with no documentation or comments making troubleshooting, modifications, and system upgrades extremely risky and time-consuming.

Integration Difficulties

Inability to connect modern sensors, monitoring systems, or enterprise software due to outdated protocols and closed proprietary systems.

Platform Lock-In

Proprietary systems that limit your options, make you dependent on single vendors, and prevent competitive pricing for upgrades and support.

What's Included

PLC Programming

Custom ladder logic and function block programming tailored to your control requirements and operational processes.

HMI Design

Intuitive graphical interfaces for system monitoring, control, and data visualisation with clear alarms and trending.

System Integration

Connect PLCs with sensors, drives, temperature monitoring, SCADA systems, and other control equipment seamlessly.

Documentation & Training

Complete program documentation, logic descriptions, operator training materials, and ongoing technical support.

Why Choose JBB Electrical for PLC Programming

Our automation team brings proven expertise in PLC and SCADA systems across food manufacturing, refrigeration, and process industries.

Multi-platform expertise across Siemens, RDM, Allen Bradley, and Mitsubishi systems

Comprehensive documentation including functional specifications and control narratives

Future-proof design ensuring systems can adapt as your operations evolve

Rigorous testing and commissioning procedures with full FAT/SAT protocols

Ongoing support and modification services backed by 40+ years of experience

Our PLC Development Process

A structured approach ensuring your automation systems are delivered on time, on budget, and optimised for your operations.

Requirements Analysis

Understanding Your Needs

We map out your control requirements, process flows, equipment specifications, and operational objectives through detailed consultation with your team.

Programming & Development

Custom Logic Creation

Our engineers develop PLC programs and HMI graphics tailored to your specifications, with clear documentation and version control throughout.

Testing & Commissioning

Validation & Deployment

Comprehensive factory acceptance testing followed by on-site commissioning ensures reliable operation before going live in your facility.

Training & Support

Knowledge Transfer

We train your team on system operation and provide ongoing support for modifications, optimisation, and troubleshooting as needed.

Related Services

Control Panels & MCC Design

Professional control panel design and manufacturing services for industrial and commercial applications. From concept to commissioning, we deliver bespoke solutions that meet your exact specifications and comply with all relevant standards.

Learn MoreElectrical Installations & Design

Professional electrical installation services from initial planning through to final certification. Our experienced team delivers safe, compliant installations for industrial, commercial, and food production environments.

Learn MoreTemperature Monitoring

Comprehensive temperature monitoring systems for compliance and quality control. Our solutions provide continuous data logging, real-time alerts, and detailed reporting to meet HACCP and regulatory requirements.

Learn MoreWhat Our Clients Say

Trusted by operations and engineering leaders across the UK

"I have worked with the team at JBB Electrical on a wide range of projects and reactive works for over 15 years. They consistently complete jobs to an excellent standard and are always a pleasure to deal with. Their technical knowledge is a huge benefit to both myself and my customers, and nothing is ever too much trouble for the team. They regularly go above and beyond, and I would not hesitate to recommend JBB Electrical"

Ian Ross

Service Manager, EJM

"The team at JBB Electrical have been integral to the implementation of the proof-of-concept large scale energy‑sharing district heating & cooling network at SmartParc’s food production campus in Derby. JBB’s wealth of knowledge and experience in industrial controls and automation helped integrate the multiple systems and platforms required for seamless control and monitoring of the energy centre plant and park network. JBB have also secured and successfully delivered the electrical subcontract works associated with the industrial cooling installations for all tenants on the park thus far. All under competitive tender and ambitious installation programmes. All projects have been completed on time, within budget and to the highest quality standards. I can highly recommend JBB as partner of choice for complex industrial electrical and automation projects."

Mike Roberts

Senior Technical Manager, SmartParc

Frequently Asked Questions

Find answers to common questions about our electrical installation services

Explore Our Resources

Stay informed with our latest guides, insights, and technical articles on electrical installations and industrial systems.

Why Industrial Circuit Breakers Trip in Industrial Systems

Developing a Critical Spares Strategy for Industrial Facilities