Cookie Preferences

We use cookies to enhance your experience and analyze site usage.

By clicking "Accept All", you consent to the use of all cookies. Click "Customize" to choose which categories to enable, or "Reject All" to only use strictly necessary cookies. Learn more in our Cookie Policy

Temperature Probe Calibration That Ensures Accuracy, Compliance & Product Safety

From warehouse temperature mapping to continuous monitoring systems. We calibrate temperature probes to traceable standards, ensuring reliable data for food manufacturing, pharmaceuticals, and cold storage environments.

Trusted by UK manufacturers in food, building management systems, refrigeration & process engineering

Temperature Calibration Built for Regulatory Compliance

Every probe we calibrate is verified against UKAS-traceable reference standards, ensuring accurate measurement data and audit-ready documentation

Traceable Standards

UKAS-Traceable Calibration

All calibration performed against reference standards traceable to national measurement institutes, ensuring accuracy and providing audit-proof documentation for regulatory compliance.

Multi-Point Verification

Full Compliance Coverage

Calibration at multiple temperature points across your operational range, ensuring accuracy throughout cold storage, ambient, and heated zones.

Risk Prevention

Regulatory & Product Protection

Regular calibration prevents product spoilage, failed audits, costly recalls, and regulatory penalties caused by inaccurate temperature monitoring data.

Whether you need annual calibration for a single warehouse or comprehensive temperature monitoring validation across multiple sites, our team has the precision equipment and regulatory knowledge to deliver exactly what your operation requires.

Discuss Your RequirementsProfessional Temperature Probe Calibration

For over four decades, JBB has been protecting temperature-critical operations through precision calibration services for warehousing, food manufacturing, and pharmaceutical facilities. From handheld probe verification to fixed monitoring system calibration, we bring systematic accuracy and compliance documentation to every measurement point.

Assessment & Planning

Understanding Your Requirements - We review your monitoring systems, operational temperature ranges, regulatory requirements, and calibration frequency needs to create optimal calibration schedules.

Traceable Calibration

Standards-Based Verification - Using UKAS-traceable reference equipment, we verify probe accuracy at defined temperature points.

Temperature Mapping

Operational Validation - Complete warehouse temperature mapping using calibrated data loggers to identify hot and cold spots, validate HVAC performance, and optimize permanent probe placement.

Documentation & Certification

Audit-Ready Records - You receive formal calibration certificates detailing procedures, equipment used, measurement results, and traceability chain for regulatory compliance and quality management systems.

Common Temperature Calibration Challenges We Solve

Uncalibrated or poorly maintained temperature probes create operational headaches that impact your business

Measurement Drift

Temperature probes naturally drift over time due to wear, environmental factors, and electrical stress, causing inaccurate readings that compromise product safety.

Regulatory Non-Compliance

Failure to maintain documented calibration records leads to failed audits, regulatory penalties, and potential operational shutdowns during inspections.

Product Loss Risk

Inaccurate temperature monitoring results in undetected storage condition deviations, causing product spoilage, degradation, and costly batch losses.

Missing Traceability

Lack of UKAS or NIST-traceable calibration documentation fails to meet ISO 9001, HACCP, GDP, and GMP requirements for measurement accuracy.

False Alarm Fatigue

Poorly calibrated systems generate unreliable alerts, wasting time investigating non-existent problems while potentially missing genuine temperature excursions.

What's Included in Our Service

From initial assessment to ongoing calibration management, we handle every aspect of your temperature monitoring accuracy

On-Site Calibration

We calibrate fixed and portable temperature probes at your facility using traceable reference standards, minimizing disruption to your monitoring systems.

Multi-Point Verification

Each probe is verified at multiple temperature points across your operational range, ensuring accuracy for cold storage, ambient, and process applications.

Temperature Mapping

Complete facility mapping using calibrated data loggers identifies environmental variations, validates HVAC performance, and determines optimal permanent probe locations.

Calibration Certification

You receive detailed calibration certificates showing equipment used, measurement results, uncertainty calculations, and full traceability chain for audit compliance.

Why Choose JBB for Temperature Probe Calibration

With over 40 years serving temperature-critical industries, we deliver calibration services that meet the highest standards of accuracy, compliance, and traceability.

40+ years calibrating temperature systems for food manufacturing, pharmaceuticals, and cold storage facilities

UKAS-traceable reference standards ensuring measurement accuracy aligned with national and international requirements

Complete temperature mapping services identifying hot and cold spots for optimal monitoring system design

Ongoing calibration management including scheduling, documentation, and compliance record maintenance

Our Temperature Calibration Process

A proven methodology that ensures accuracy, compliance, and reliable temperature monitoring

Requirements Assessment

Understanding Your Monitoring Needs

We review your facility layout, temperature-critical zones, regulatory requirements, and existing monitoring systems to establish calibration scope and frequency.

Calibration & Verification

Standards-Based Testing

Using traceable reference equipment, we verify each probe at defined temperature points, documenting deviations and performing adjustments where required.

Certification & Reporting

Documentation & Compliance

You receive formal calibration certificates, and recommended monitoring improvements with full traceability for regulatory audits and quality systems.

Related Services

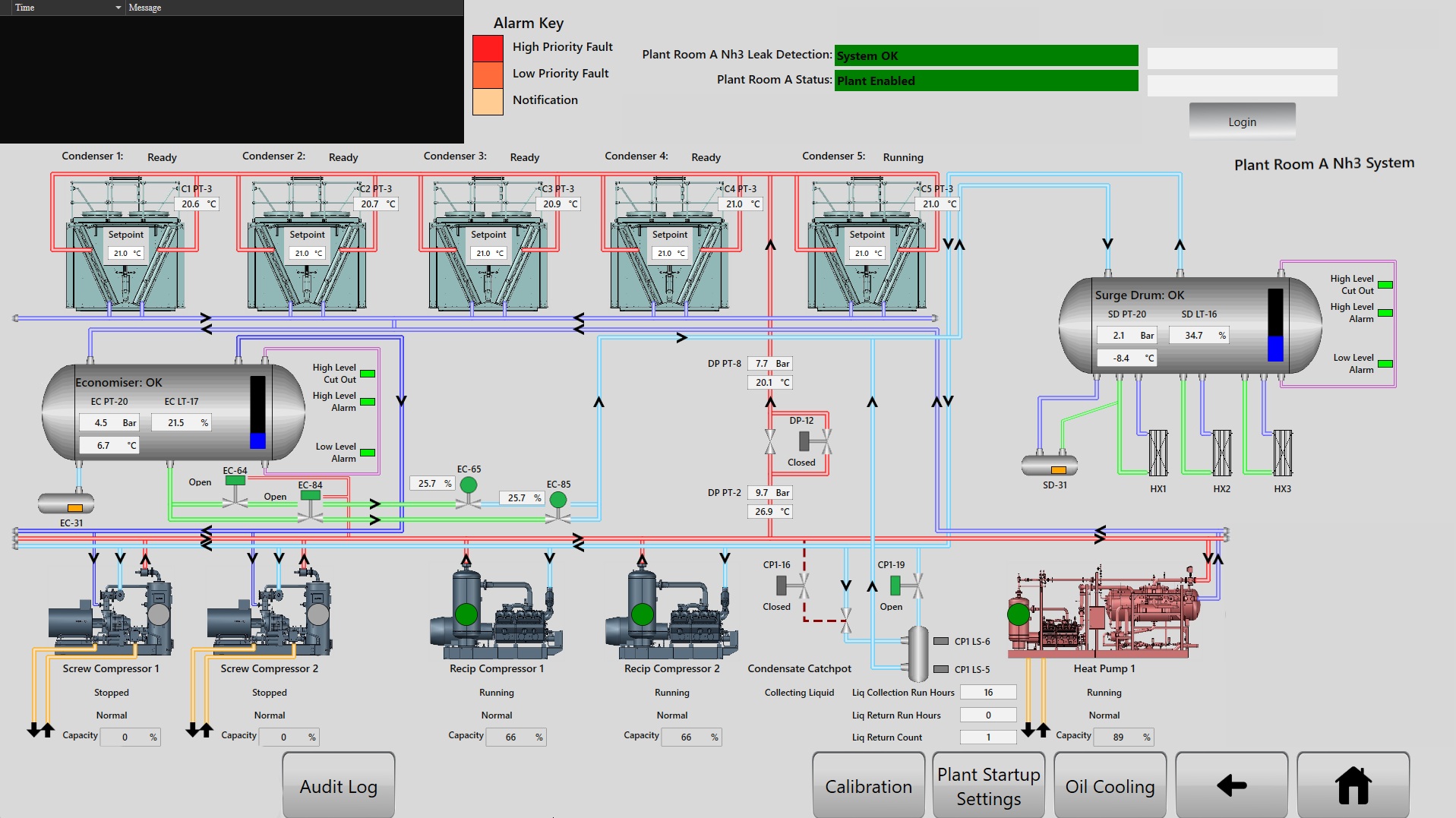

Refrigeration Control Systems

Advanced refrigeration control solutions for food production and cold storage facilities. Our systems ensure precise temperature management, energy efficiency, and full compliance with food safety regulations across all applications.

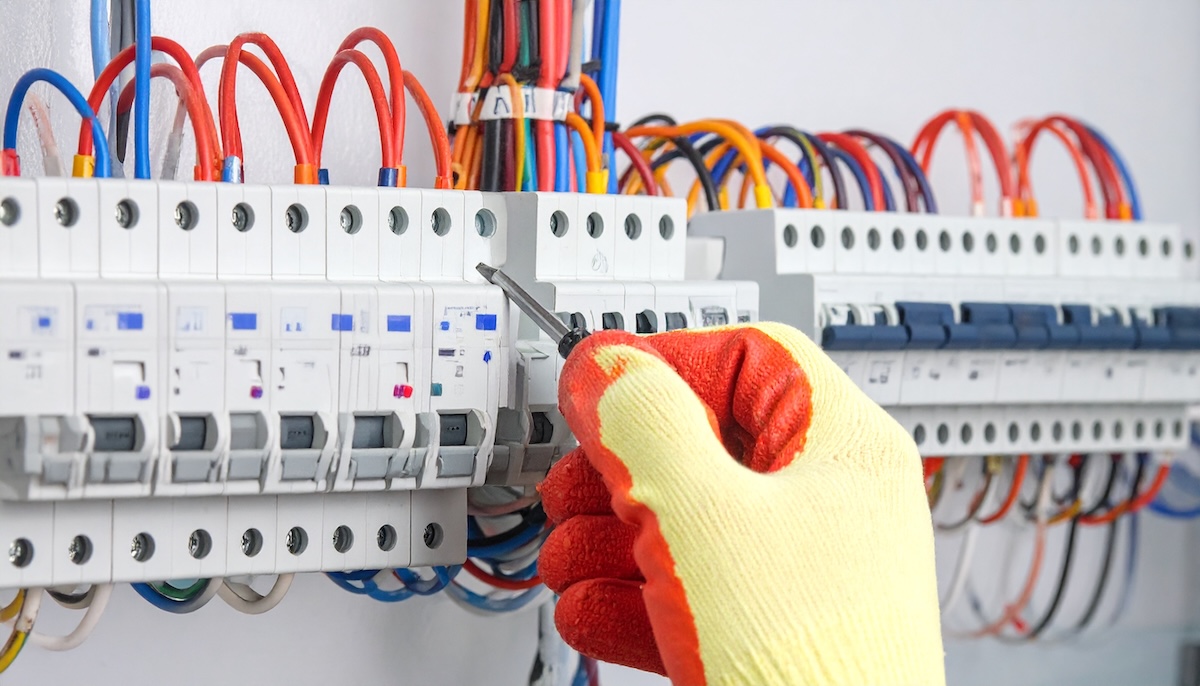

Learn MoreControl Panels & MCC Design

Professional control panel design and manufacturing services for industrial and commercial applications. From concept to commissioning, we deliver bespoke solutions that meet your exact specifications and comply with all relevant standards.

Learn MorePreventive Electrical Maintenance

Planned preventative maintenance programmes designed to maximise equipment reliability and minimise unexpected downtime. Our proactive approach keeps your electrical systems operating at peak performance.

Learn MoreWhat Our Clients Say

Trusted by operations and engineering leaders across the UK

"I have worked with the team at JBB Electrical on a wide range of projects and reactive works for over 15 years. They consistently complete jobs to an excellent standard and are always a pleasure to deal with. Their technical knowledge is a huge benefit to both myself and my customers, and nothing is ever too much trouble for the team. They regularly go above and beyond, and I would not hesitate to recommend JBB Electrical"

Ian Ross

Service Manager, EJM

"The team at JBB Electrical have been integral to the implementation of the proof-of-concept large scale energy‑sharing district heating & cooling network at SmartParc’s food production campus in Derby. JBB’s wealth of knowledge and experience in industrial controls and automation helped integrate the multiple systems and platforms required for seamless control and monitoring of the energy centre plant and park network. JBB have also secured and successfully delivered the electrical subcontract works associated with the industrial cooling installations for all tenants on the park thus far. All under competitive tender and ambitious installation programmes. All projects have been completed on time, within budget and to the highest quality standards. I can highly recommend JBB as partner of choice for complex industrial electrical and automation projects."

Mike Roberts

Senior Technical Manager, SmartParc

Frequently Asked Questions About Temperature Monitoring

Common questions about temperature monitoring systems, compliance, and implementation

Explore Our Resources

Stay informed with our latest guides, insights, and technical articles on electrical installations and industrial systems.

Why Industrial Circuit Breakers Trip in Industrial Systems

Developing a Critical Spares Strategy for Industrial Facilities