Programmable logic controller (PLC) systems are the operational core of industrial automation. They coordinate motors, conveyors, temperature systems, pumps, safety circuits, batching processes and entire production lines. Industrial plants increasingly base their control and automation systems on PLCs, making reliable PLC operation essential for plant efficiency and safety. When a PLC fails, the effect is immediate: machinery stops, safety systems trigger, and production downtime begins within seconds. Because modern facilities depend on continuous real-time control, even minor PLC faults can halt entire operations.

Many facilities underestimate how frequently PLC issues contribute to downtime. Failures are often misdiagnosed as mechanical faults, electrical supply issues or operator error. In reality, PLC failures are one of the most common root causes of production stoppages across food manufacturing, cold storage, logistics, automotive assembly, process engineering and packaging environments. When an industrial plant fails due to PLC issues, the impact can be severe, affecting plant output and operational continuity.

This engineering-led guide explains how PLC failures lead to downtime, the common technical causes, compliance drivers, operational risks and the preventive measures required to maintain reliability. It draws from JBB Electrical’s extensive experience diagnosing PLC failures across industrial sites where uptime is critical.

💡 Key Insight:

PLC failures rarely occur suddenly. They typically develop from small electrical, software or hardware issues that remain undetected until they trigger a critical shutdown. PLCs have evolved from earlier relay logic systems, enabling more complex and reliable automation.

The Role of PLCs in Industrial Production

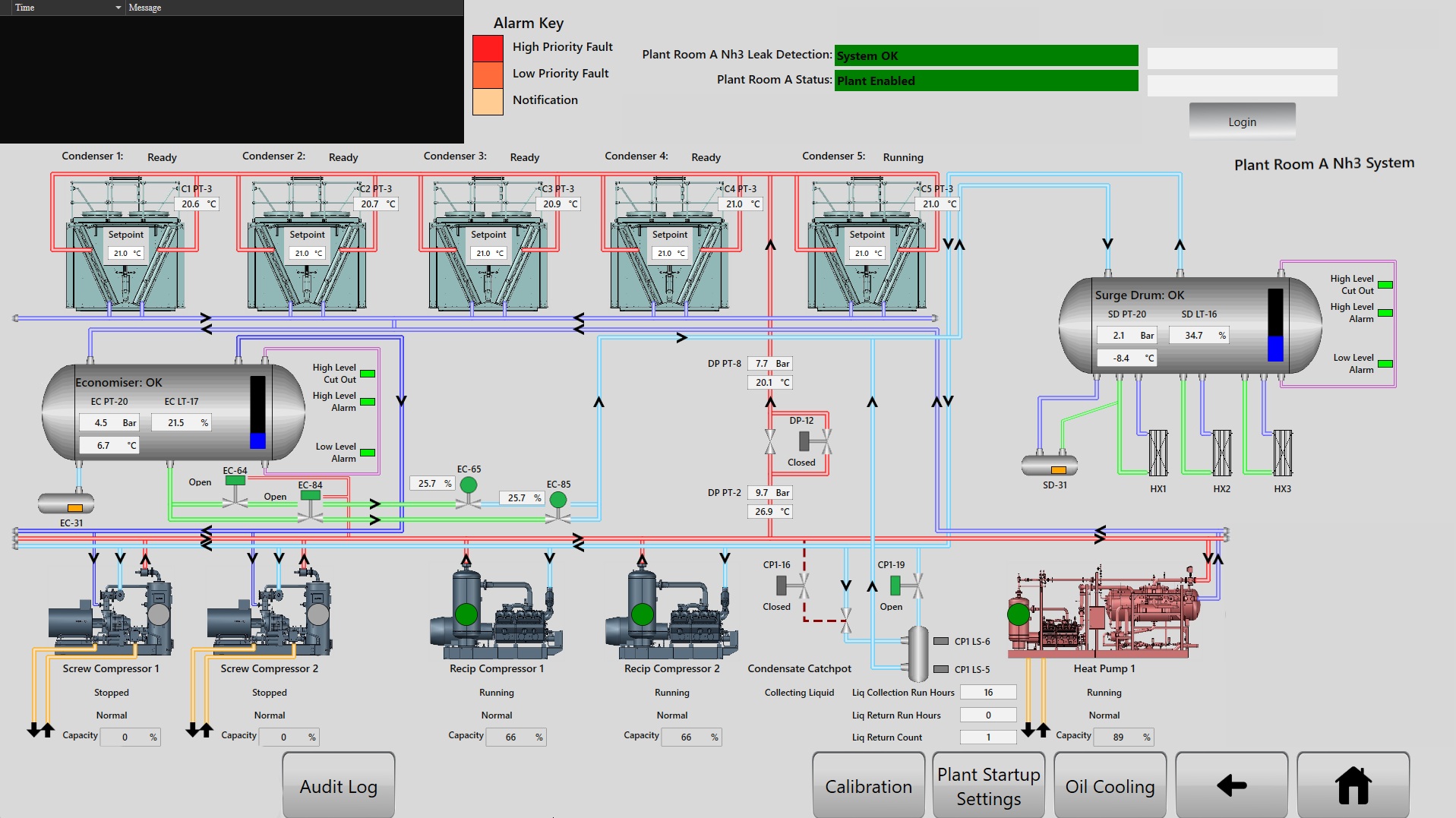

A PLC is a ruggedised industrial computer designed to control plant equipment in real time. Unlike standard computers, PLCs operate continuously under harsh conditions — vibration, heat, electrical noise, moisture and load fluctuations. Their purpose is to execute logic instructions that determine when equipment runs, stops, sequences, interlocks or triggers alarms.

In modern production environments, PLCs provide control for:

conveyor systems and automated handling lines

mixing, batching and dosing sequences

packaging lines and filling systems

temperature and refrigeration plant

pumps, fans, compressors and motors

safety systems including emergency stops

SCADA and HMI visualisation systems

PLC technology is central to automated industrial processes, enabling reliable and efficient operation across a wide range of industrial applications.

Because so many systems rely on PLCs, any failure has a broad and immediate impact. A seemingly minor PLC issue, such as a failed I/O module or corrupt data block, can stop a full production line worth hundreds of thousands of pounds per hour.

Why PLC Failures Cause Immediate Downtime

PLC systems are designed with strict safety priorities. If the PLC stops functioning, loses communication or detects inconsistent logic, it will default to a safe state. In most cases, this means shutting down machinery. This safety-first design prevents injury and equipment damage but makes PLC reliability essential. Most PLC control systems are designed as a robust control system to ensure the control system operates continuously, but failures can still disrupt industrial automated processes.

Downtime caused by PLC failure normally occurs because:

logic stops executing, halting automation

Faulty or Ageing I/O Modules

safety circuits trigger shutdowns

SCADA loses communication and data can be come corrupt or lost

motors and conveyors stop responding to commands

PLC enters a fault state requiring manual reset

Unlike mechanical systems, PLCs cannot partially operate. When they fail, they stop completely, and everything they control stops with them.

⚠ Critical Warning:

PLC failures cascade instantly across production systems because they remove the central decision-making and sequencing logic that keeps automated equipment in sync.

The 11 Most Common Causes of PLC Failure

PLC failures can originate from hardware, software, electrical, environmental or operational causes. PLCs often operate in harsh industrial environments, where factors like high temperatures, humidity, dust, and electrical interference can accelerate wear and increase the risk of system failures.

Maintaining reliable and secure operation in challenging industrial environments requires careful attention to factors such as proper grounding and ground integrity, which help prevent electrical noise, interference, and ensure the safety and reliability of the control system.

Below are the most frequent issues JBB Electrical engineers identify across industrial sites.

1. Power Supply Failure

PLCs rely on stable 24V DC power supplies. A failing PSU can cause intermittent resets, corrupted memory, communication dropouts or full shutdowns. Power supply issues often arise from:

overheating in control panels

ageing components

loose terminals

voltage dips or surges

end-of-life hardware

a tripped circuit breaker

Redundant power systems, such as uninterruptible power supplies (UPS) and backup batteries, are essential to prevent downtime during a power outage or even a minor power loss incident.

Often, PLC failures attributed to software faults originate from degraded power supplies. To safeguard PLC operation and memory during power interruptions, it is recommended to install uninterruptible power supplies.

2. Overheating Inside Control Panels

Excessive heat accelerates component failure and causes PLCs to freeze, reset or shut down. Overheating is frequently caused by blocked vents, failed cooling fans or dense panel layouts.

Dedicated panel cooling systems and regular servicing of air filtration components are critical for maintaining optimal temperatures and preventing overheating. High power components within control panels can generate significant heat, making effective cooling and ventilation essential.

📊 Industry Statistic:

Many sudden PLC failures investigated involved elevated control panel temperatures visible on thermal imaging data.

3. Faulty or Ageing I/O Modules

I/O modules are the interface between the PLC logic and the real-world equipment. When these modules fail, sensors, motors and actuators stop responding correctly. Identifying the exact input or output point where a fault occurs is crucial for effective troubleshooting and minimizing downtime. Faults include:

analog signal drift

digital output failures

intermittent connections

noise interference

faulty input components such as sensors or switches

Module failure can often be traced to issues with field devices connected to the I/O modules.

4. Electrical Noise and Interference

VFDs, motors, switching devices and poorly segregated wiring can introduce electrical noise that disrupts PLC operation. Noise can cause random resets, false signals and logic instability.

Electromagnetic interference (EMI) and radio frequency interference (RFI) are common sources of electrical noise in industrial settings.

To control electrical noise and reduce the risk of PLC failure downtime, it may be necessary to relocate sensitive equipment, shield cables, and improve grounding.

5. Loose Terminations and Wiring Failures

Loose terminals are one of the most common causes of intermittent PLC faults. Heat cycles, vibration and age gradually loosen terminations, causing voltage drop or signal loss.

Loose connections and loose terminal blocks are frequent sources of PLC faults, as they can disrupt electrical continuity and lead to irregular signals or complete system failures.

Loose wiring often causes symptoms such as:

intermittent I/O signals

unexpected resets

sensor faults

module communication errors

To ensure electrical safety and system reliability, always inspect ground wiring and test the PLC ground terminal during maintenance and troubleshooting.

6. Software Corruption or Program Errors

Software faults can be caused by incorrect programming, corrupt memory, power loss during writes or poorly managed revisions. The risk is higher in facilities without version control or documentation.

Software glitches PLCs rely on can cause unexpected failures if not properly managed.

❌ Common Mistake:

Relying on old, undocumented PLC programs is extremely risky. If the PLC fails, recovery becomes slow, costly and may require full redevelopment. PLC configuration errors, such as incorrect parameter settings, can also disrupt operation.

Internal PLC errors may manifest as erratic behaviour or process stops, and regular maintenance of PLC software and verification of PLC program logic are essential for reliability.

7. End-of-Life PLC Hardware

Many older industrial PLC systems have been discontinued, spare parts are increasingly difficult to find, and the associated software is no longer supported. Legacy systems with obsolete PLC based control systems pose a significant risk, as sourcing replacement parts for outdated equipment can be challenging and may lead to extended downtime.

firmware cannot be updated

components degrade

programming software becomes obsolete

migration becomes increasingly urgent

As these systems age, the PLC's internal components are more susceptible to failure, further increasing the risk of plc failure downtime.

8. Environmental Contamination

Dust, moisture, oil mist and temperature fluctuations accelerate degradation of circuitry and connectors.

Harsh industrial environments can accelerate contamination and degradation of equipment and control systems, increasing the risk of PLC failure downtime.

cold stores introduce condensation risks

food plants introduce particulate contamination

heavy industry introduces vibrational stress

Regular inspection and maintenance of electrical equipment is essential to prevent failures and ensure reliable operation in these challenging conditions.

9. Communication Network Issues

Modern PLCs depend on fieldbus networks (Profibus, Ethernet/IP, Profinet, Modbus). If communication fails, automation becomes unstable. Network communication errors, such as lost connections or dropped data, can disrupt automation and lead to unexpected downtime.

Network issues occur due to:

damaged cables

EMC interference

misconfigured switches

broken connectors

failing communication cards

problems with the typical communication medium, such as industrial Ethernet, which can cause downtime

Maintaining a reliable industrial network and physical network infrastructure, as well as integrating other industrial networks, is essential for continuous operation.

10. Incorrect Modifications or Unmanaged Changes

Changes to PLC logic, wiring or I/O without documentation create hidden risks. A modification made to solve one issue can introduce a new fault elsewhere.

11. Backup, Firmware and Software Neglect

PLCs require periodic backups, firmware updates and documentation reviews. Many facilities run outdated firmware for years, unaware that critical bugs or vulnerabilities exist. It is essential to back up PLC software regularly to prevent data loss and ensure quick recovery after failures.

⚠ Compliance Warning:

Facilities running outdated PLC firmware or missing program backups risk extended downtime if hardware fails or software becomes corrupted. Loss of process data during a failure can result in a major system failure, causing significant operational disruption and prolonged downtime.

How PLC Failures Affect Production Systems

Because PLCs sit at the heart of automation, their failures propagate across entire systems. A PLC control system failure can propagate rapidly, causing widespread system failures that disrupt production and increase downtime. The effects vary depending on plant layout, type of equipment and PLC role, but common consequences include:

Understanding why PLC control systems fail is essential for effective troubleshooting and maintaining reliable PLC control.

1. Immediate Production Shutdown

If the PLC controls safety circuits, conveyors, batching equipment or critical sequencing, machinery stops instantly.

2. Unpredictable or Dangerous Equipment Behaviour

PLCs ensure coordinated operation. When they fail, motors may start or stop unexpectedly, or equipment may become unresponsive.

3. Loss of SCADA Visibility

When a PLC fails, SCADA systems lose communication, making diagnosis difficult and slowing response time.

Additionally, human-machine interfaces (HMIs) may also lose communication with the PLC, further complicating diagnosis and control.

4. Inconsistent Temperature Control

PLCs often control cold stores, ovens and HVAC systems. A PLC fault can trigger temperature excursions and compliance breaches.

5. Batch Loss and Product Rejection

If a PLC controls dosing or mixing, an error can ruin a full batch.

6. Safety Circuit Activation

Most PLC faults default equipment into a safe state, resulting in e-stop activation or line stops.PLC Failure: Early Warning Indicators

Identifying early warnings prevents downtime. PLC issues nearly always present subtle signs before total failure.

random or intermittent resets

analog values drifting without cause

communication dropouts

unexpected alarm triggers

overheated I/O modules

unusual panel temperature trends

I/O flickering or signal loss

PLC entering STOP mode without clear rationale

PLC Failure: Early Warning Indicators

Identifying early warnings prevents downtime. PLC issues nearly always present subtle signs before total failure.

random or intermittent resets

analog values drifting without cause

communication dropouts

unexpected alarm triggers

overheated I/O modules

unusual panel temperature trends

I/O flickering or signal loss

PLC entering STOP mode without clear rationale

Engineering Controls That Prevent PLC Failures

Preventive engineering, modernisation and compliance-based design are essential to reducing PLC downtime. Service managers play a key role in overseeing preventative maintenance and coordinating repairs, while service engineers provide specialized technical assistance to identify and resolve issues, ensuring reliable electromechanical functions and minimizing the risk of PLC failure downtime. Below are the most effective strategies JBB Electrical deploys.

1. Control Panel Modernisation

Aging control panels are one of the biggest contributors to PLC failures. Upgrading wiring, cooling, layout and protection improves PLC reliability dramatically.

new BS EN 60204-1 compliant wiring

dedicated cooling fans and filtered ventilation

segregated low-voltage and power wiring

new power supplies with stable DC output

2. PLC Hardware Migration

End-of-life PLCs must be migrated to supported platforms. JBB provides PLC migration pathways that preserve functionality while improving reliability and cyber readiness.

3. Improved Environmental Protection

Sealing, ventilation, heating and cabinet enclosures must be appropriate for site conditions such as cold storage, high dust or vibration.

4. Wiring Integrity Improvements

Torque checks, cable management improvements, reterminations and insulation upgrades prevent intermittent PLC faults.

5. Reliable Power Supply Design

Stable power distribution, clean DC power and proper electrical protection help avoid sudden resets.

6. Software Management & Version Control

PLC programs should be documented, backed up and version-controlled. Engineers should maintain clear change logs for every logic modification.

7. Communication Network Upgrades

Replacing old Profibus runs, damaged connectors or outdated switches eliminates many intermittent faults.

Preventive Maintenance for PLC Reliability

Preventive maintenance is essential. PLCs and control panels degrade slowly over time and require structured inspection.

Activities include:

thermal imaging under load

torque checks on terminals

insulation and wiring condition inspections

power supply output verification

sensor and actuator testing

PLC program backups

firmware updates

communication diagnostics

☑ PLC Reliability Maintenance Checklist

Check control panel temperatures

Inspect I/O drift and anomalies

Validate communication health

Verify DC supply stability

Review logs for unexpected resets

Check environmental seals

Log all program version updates

JBB’s Engineering-Led Approach to Preventing PLC-Caused Downtime

JBB Electrical applies its lifecycle methodology to reduce PLC failure risk:

JBB's diagnostics include thorough inspection of the PLC's central processing unit and PLC control module to identify potential failure points.

📋 JBB PLC Reliability Framework

Assess – Control panel condition surveys, PLC diagnostics, software audits, thermal analysis.

Modernise – Hardware upgrades, PLC migrations, wiring improvements, PSU replacement.

Protect – Surge protection, improved EMC management, enclosure upgrades.

Prevent – Preventive maintenance, monitoring, software version control.

Support – Ongoing PLC support, remote diagnostics, and compliance reporting.

FAQs

What risks does this issue create?

PLC failures can halt production instantly, trigger safety shutdowns, cause product loss, compromise temperature control, disrupt automation and create compliance issues.

How does compliance affect this?

PLCs must operate within BS EN 60204-1 and BS7671 requirements. Poorly maintained or undocumented systems increase compliance and insurance risk.

What preventive measures should be taken?

Preventive maintenance, PLC migration, environmental protection, power stability improvements, thermal imaging and proper documentation significantly reduce failure risk.

How do modern systems improve reliability?

Modern PLCs offer enhanced diagnostics, stable hardware, better communication networks, energy efficiency and significantly reduced downtime risk.

Next Step: Request a Compliance & Breakdown Prevention Assessment

If your PLCs are ageing, unreliable or showing early signs of failure, a structured engineering review is essential. JBB’s Compliance & Breakdown Prevention Assessment identifies control panel risks, software issues, electrical degradation and opportunities for modernisation. Our engineers provide a clear plan to protect uptime, reduce risk and improve operational reliability.

Request a Compliance & Breakdown Prevention Assessment today to protect your production operation from PLC-related downtime.