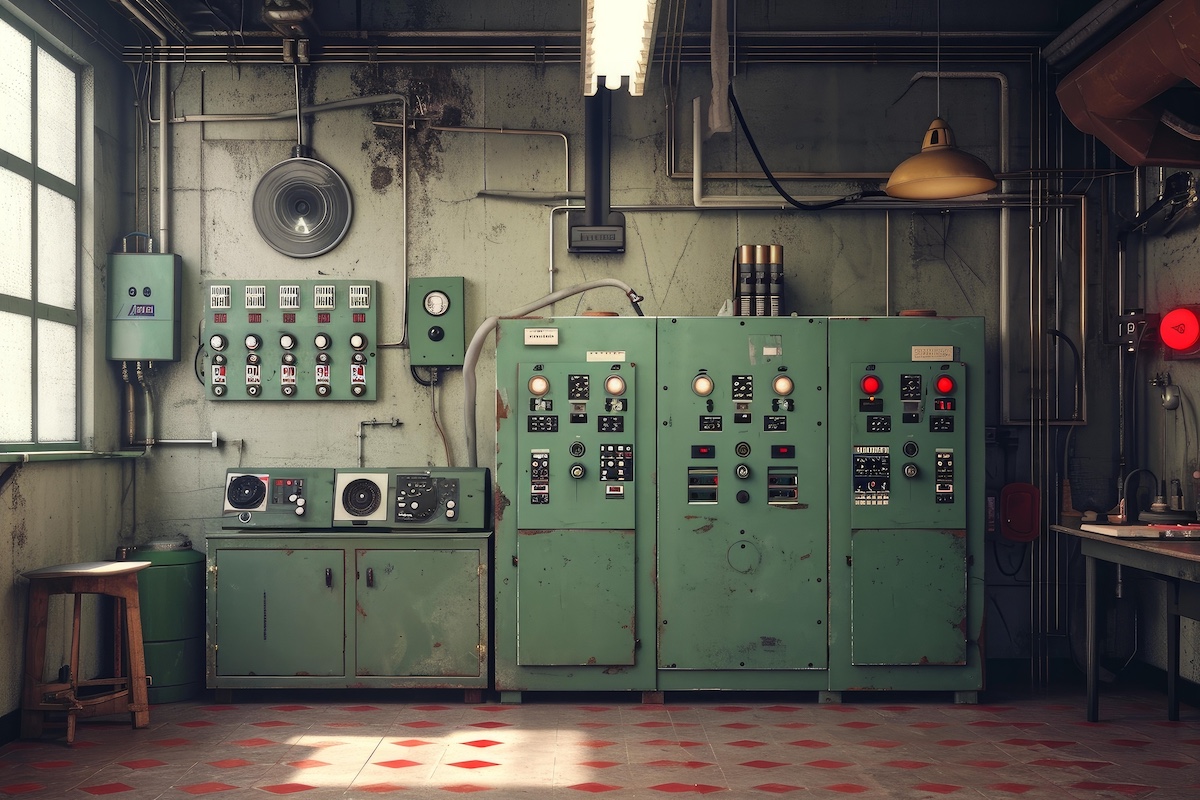

Control panels are the operational backbone of industrial electrical systems. They manage machinery, refrigeration plant, production line sequencing and real-time automation logic. When panels reach the end of their usable life, the risk to production, compliance and safety increases exponentially. Many industrial sites operate control panels that appear functional on the surface but are dangerously outdated internally. Old panels may continue to run but can hide significant risks that threaten system reliability and safety.

For food manufacturing, cold storage, pharmaceuticals, process engineering and other continuous-production environments, an end-of-life control panel is not simply an inconvenience. A single unexpected panel failure can shut down an entire production line or refrigeration system, triggering product loss, downtime penalties, contamination risk and significant repair costs.

💡 Key Insight:

Ageing wiring, outdated components, lost documentation, increasing temperatures and obsolete PLC hardware often remain hidden until a critical failure occurs. Recognising warning signs such as overloaded circuits, frequent breaker trips, or unusual noises is essential to identifying end-of-life panels before failure.

Introduction to Control Panels

Control panels are the backbone of any electrical system, providing centralized control and monitoring for a wide range of electrical equipment and processes. A well-designed control panel is essential for maintaining electrical safety, achieving optimal performance, and ensuring the smooth operation of your facility. At BEES, we understand that every application has unique requirements, which is why we offer custom control panel solutions tailored to your operational goals. Our experienced electrical engineers work closely with clients from the initial concept through to installation, ensuring that each panel is engineered for energy efficiency, reliability, and full compliance with regulatory requirements.

What Does End-of-Life Mean for a Control Panel?

End-of-life in industrial control panels refers to the stage where components, wiring, protective devices, cooling systems, layout, documentation or safety functions no longer meet engineering, compliance or operational requirements. This does not necessarily mean the panel is non-functional. Instead, it means the panel cannot be operated reliably, safely or economically without modernisation.

End-of-life typically results from:

component ageing beyond manufacturer support

heat stress and wiring degradation, which can compromise the electrical panel's ability to maintain safety and compliance

obsolete PLC or SCADA platforms

lack of documentation or revision control

inadequate cooling or poor design by today’s standards

non-compliance with BS EN 60204-1 and BS7671

load growth far beyond the panel’s original design

The challenge for engineering and operations teams is that many early failure indicators are not visible.

Why Industrial Control Panels Fail Over Time

Control panels fail through a combination of mechanical, electrical and thermal stress. Even in well-maintained facilities, panels degrade due to environmental factors, continuous load, vibration, heat and modifications made over the years of operation.

The most common reasons include:

Thermal cycling – repeated heating and cooling loosen terminals and break down insulation.

Obsolete components – manufacturers discontinue PLCs, contactors, overloads and relays, making replacements unavailable.

Wiring fatigue – insulation hardens, becomes brittle, or shows signs of cracking over time, which can compromise electrical circuits and increase the risk of faults.

Load creep – production expansions increase circuit loads beyond the panel’s original capacity, putting additional stress on electrical circuits.

Cooling fan failure – fans degrade gradually, causing compounding heat issues.

Documentation loss – undocumented modifications accumulate, creating unknown risks.

Moisture, dust and contaminants – especially in food, logistics and chilled environments.

These issues can lead to short circuit events, which pose significant safety hazards such as arcing, overheating, and potential electrical fires.

⚠ Critical Warning:

Panels rarely fail due to a single catastrophic event. Failure is usually the end result of years of small, undetected issues such as loose terminals, rising temperatures and obsolete hardware.

Electrical Enclosures and Safety

Electrical enclosures are a vital part of any control panel, serving as the first line of defence against electrical shock, fire risks, and environmental hazards. The right enclosure not only protects sensitive electrical components from dust, moisture, and accidental contact but also plays a key role in maintaining overall electrical safety. At BEES, we prioritise the use of high-quality electrical enclosures that meet or exceed industry standards and IET wiring regulations. Our skilled engineers ensure that every panel is fully compliant with all relevant regulatory requirements, providing peace of mind that your electrical equipment is protected against fire hazards and other safety risks.

The Engineering Signs of an End-of-Life Control Panel

Identifying end-of-life control panels requires a combination of physical inspection, electrical testing, thermal imaging, lifecycle status checks, and documentation analysis. Understanding the original panel design is crucial for accurate assessment, as it provides insight into the intended operational requirements, safety standards, and future scalability of the control panel. Below are the key signs that indicate a panel is at or near the end of its safe and reliable operating life. Additionally, issues in the original assembly process—such as poor wiring or improper integration of components—can contribute to premature end-of-life.

1. Ageing or Obsolete Components

If a panel contains PLCs, relays, contactors, power supplies, transformers or other devices that have been discontinued by the manufacturer, the system is already at risk. Once support ends, firmware, spares and safety notices cease to be available. Panels built with high quality components sourced from trusted suppliers are less likely to experience premature failure, as these components are selected for their reliability, performance, and compatibility with the system.

lack of spares availability

no firmware updates or security patches

risky reliance on ageing proprietary software

inability to integrate with modern systems

❌ Common Mistake:

Obsolete PLCs can fail without warning, leaving no repair pathway due to unavailable parts or software.

2. Thermal Stress and Overheating

Thermal imaging is one of the most effective ways to identify end-of-life conditions. Persistent hotspots indicate resistance, loose terminals, overloaded circuits or component failure.

contactors running hotter than normal

overheated VSDs or PSUs

hotspots on neutral or earth bars

discolouration of wiring insulation

Early detection of these thermal issues leads to reduced downtime and improved reliability.

📊 Industry Statistic:

A lot of panel failures investigated involve thermal anomalies that were visible on infrared surveys months before failure.

3. Wiring Degradation and Insulation Breakdown

End-of-life panels often contain wiring that has hardened, cracked or lost flexibility. This is common in older panels or those exposed to vibration, temperature cycling or poor ventilation.

brittle insulation

cracked sheathing

discoloured or darkened conductors

loose or damaged terminations

Such wiring increases the risk of short-circuits, arcing, intermittent faults and fire hazards.

4. Poor Cooling and Failed Ventilation

Cooling fans, filters and thermal management systems naturally degrade over time. When they stop working effectively, internal panel temperatures rise, accelerating component ageing and reducing reliability.

dust-filled or blocked fan filters

failed cooling fans

overheating of VSDs and PLCs

lack of ventilation or poor layout design

5. Signs of Water Ingress or Contamination

Panels located in cold stores, washdown areas or production spaces are at higher risk of moisture ingress. Condensation, steam, washdown overspray and airborne contaminants can all degrade wiring and components.

rust or corrosion on metalwork

water marks or staining on the enclosure

presence of condensation on wiring or terminals

accumulated dust, flour, grease or organic matter

6. Missing or Outdated Documentation

A panel with missing schematics or undocumented modifications is inherently unsafe to operate. BS EN 60204-1 requires accurate, up-to-date documentation. Lost documentation is one of the strongest indicators of system age and unmanaged modifications. Accurate records are also essential for ensuring compliance with industry standards and regulatory requirements.

❗ Critical Documentation Issue:

If you cannot verify what a panel does, how it works, or how it was modified, you cannot ensure compliance, maintenance or safe operation.

7. Repeated Nuisance Tripping

End-of-life components often cause unexplained trips, especially on circuits involving motors, refrigeration equipment or high inrush loads. While nuisance trips are often dismissed as minor, they frequently indicate deeper problems such as overloaded circuits, weak components or thermal imbalance.

8. Evidence of Past Overheating or Poor Repairs

Many older panels contain signs of previous overheating or improvised repairs, including:

scorched insulation

replaced components that don’t match original design

twisted or unlabelled wiring

oversized protective devices

These defects significantly increase breakdown risk and are clear indicators of end-of-life status.

9. Load Growth Beyond Original Design

Production lines evolve. Equipment gets added. Loads increase. Panels that were compliant 15 years ago may now be significantly overloaded due to incremental additions.

additional circuits squeezed into limited space

new motors or conveyors added without full load review

VSDs or sensors added without redesign

To ensure long-term reliability and scalability, it's important to design control panels with built-in flexibility for future upgrades, so they can accommodate evolving operational needs.

10. Non-Compliance with BS EN 60204-1 or BS7671

Non-compliance with modern standards is a strong indicator of end-of-life. Common issues include:

incorrect circuit protection

no segregation between different voltage levels

inadequate earthing arrangements

unsafe emergency stop circuit design

outdated wiring colours

For example, failure to comply with BS EN 60204-1 and BS7671 means the panel does not meet essential regulatory standards. Adhering to these regulatory standards is crucial for ensuring panel safety, legal compliance, and certification.

ℹ Engineering Note:

Compliance does not deteriorate suddenly. It erodes over time as the panel ages, components become obsolete and loads increase. By the time non-compliance is visible, end-of-life is already near.

Circuit Breaker Maintenance

Circuit breakers are essential components within control panels, safeguarding your electrical equipment from overloads, short circuits, and the risk of electrical fires. Regular maintenance of circuit breakers is crucial for preventing electrical failures and ensuring consistent system performance. At BEES, we recommend a proactive approach to circuit breaker maintenance, including scheduled inspections, cleaning, calibration, and timely replacement when necessary.

How to Assess Whether a Control Panel Is Approaching End-of-Life

A structured assessment covers multiple engineering, compliance and operational factors. JBB’s methodology identifies end-of-life using a combination of surveys, testing, inspections and lifecycle analysis. Compliance testing also plays a crucial role in verifying that panels meet industry standards and regulatory requirements during this assessment process.

📋 JBB End-of-Life Panel Assessment Framework

Assess – condition surveys, thermal imaging, visual inspections, documentation analysis and lifecycle checks.

Modernise – component upgrades, rewiring, replacement panels, PLC migrations and compliance corrections.

Protect – improved cooling, surge protection, cable management and industrial cyber readiness.

Prevent – preventive maintenance, torque checks, load monitoring and thermal baselining.

Support – ongoing servicing, documentation updates, compliance audits, engineering guidance, and ongoing technical support to ensure optimal operation and long-term reliability.

The Detailed Engineering Checks Used to Identify End-of-Life Panels

Below are the core engineering checks JBB performs during end-of-life assessments. These checks are carried out by our expert team with specialised knowledge, ensuring thorough and accurate evaluations. These checks provide a clear risk profile and identify the precise causes of degradation.

👉 Step 1: Visual Internal and External Inspection

This includes inspecting wiring condition, signs of overheating, cleanliness, corrosion, enclosure integrity and component layout.

👉 Step 2: Thermal Imaging Under Load

Thermal images identify hotspots indicating resistance, overload or component failure. Baselines are established for future comparison.

👉 Step 3: Component Lifecycle Status Check

Accurately evaluating the lifecycle status of control panel components requires extensive experience. JBB reviews the age, support status and availability of all key components including PLCs, relays, contactors, fans and PSUs.

👉 Step 4: Wiring Integrity Verification

This includes insulation checks, torque checks, termination condition assessment and routing verification.

👉 Step 5: Load Analysis and Circuit Evaluation

Load balance, overcurrent protection, VSD loading and diversity factors are reviewed to identify overloads or imbalance.

👉 Step 6: Compliance Review (BS EN 60204-1 / BS7671)

Engineers assess compliance with wiring regulations, segregation, control circuit design, safety circuits, emergency stop integrity and earthing, referencing BS EN 60204-1 / BS7671 as well as all relevant national standards. Adhering to national standards is crucial to ensure that end of life control panels meet recognized safety benchmarks during compliance reviews.

What to Do When a Control Panel Is Nearing End-of-Life

Once a panel is identified as end-of-life, the next step is developing a modernisation plan. Modernisation plans often include upgrading panels to work with automated systems, enhancing performance, safety, and efficiency. JBB engineers work with operations and maintenance teams to determine the safest and most cost-effective upgrade pathway. The goal is to achieve seamless integration with existing operations during upgrades.

1. Full Panel Replacement

For severely outdated or unsafe panels, full replacement is often the most economical long-term solution. New panels are engineered to BS EN 60204-1, use modern hardware and incorporate improved wiring and cooling. Using high quality panels ensures greater reliability, durability, and compliance with industry standards, providing superior performance and long-term savings.

2. Partial Modernisation

In some cases, replacing wiring, protective devices, PLC hardware or cooling systems can extend the panel’s service life without full replacement. Additionally, custom panels can be installed as part of targeted upgrades, allowing for improved system performance and reliability tailored to specific operational needs.

3. PLC Migration and Software Redevelopment

Obsolete PLCs require migration to modern platforms. PLC migration is essential for maintaining modern, reliable control systems that support improved equipment performance and safety. JBB provides migration pathways that preserve functionality while improving reliability and cyber readiness.

4. Compliance Corrections

Many end-of-life panels can be made safe through segregation improvements, rewiring, updated protection, and correcting emergency stop circuitry. Compliance corrections are essential to ensure these panels meet current safety standards, protecting both equipment and personnel.

FAQs

What risks does this issue create?

End-of-life panels increase the risk of electrical fires, equipment failure, downtime, unsafe operation, compliance breaches, stock loss and escalating repair costs. Failures are often sudden and severe.

How does compliance affect this?

Non-compliant panels violate BS EN 60204-1 and BS7671 requirements, increasing legal, operational and insurance risk. Compliance issues often signal end-of-life conditions such as ageing wiring or unsafe circuitry.

What preventive measures should be taken?

Regular inspections, thermal imaging, torque checks, lifecycle analysis, documentation updates, PLC migration planning and scheduled preventive maintenance reduce the risk of failure. Proactive maintenance and regular assessments represent the best solution for preventing failures in end-of-life control panels.

How do modern systems improve reliability?

Modern panels use improved wiring, safer components, enhanced cooling, updated PLCs and better protection devices. These features reduce downtime and extend equipment lifespan.

Next Step: Request a Compliance & Breakdown Prevention Assessment

If you suspect your control panels may be approaching end-of-life, JBB Electrical can provide a structured, engineering-led assessment. As part of our upgrade services, we deliver high-quality control panels that meet rigorous industry standards. Our Compliance & Breakdown Prevention Assessment utilises the latest technology to identify risks, document lifecycle status, review compliance gaps, and provide a clear modernisation plan.

Request a Compliance & Breakdown Prevention Assessment today to protect uptime, improve safety and ensure your electrical infrastructure is future-proof.