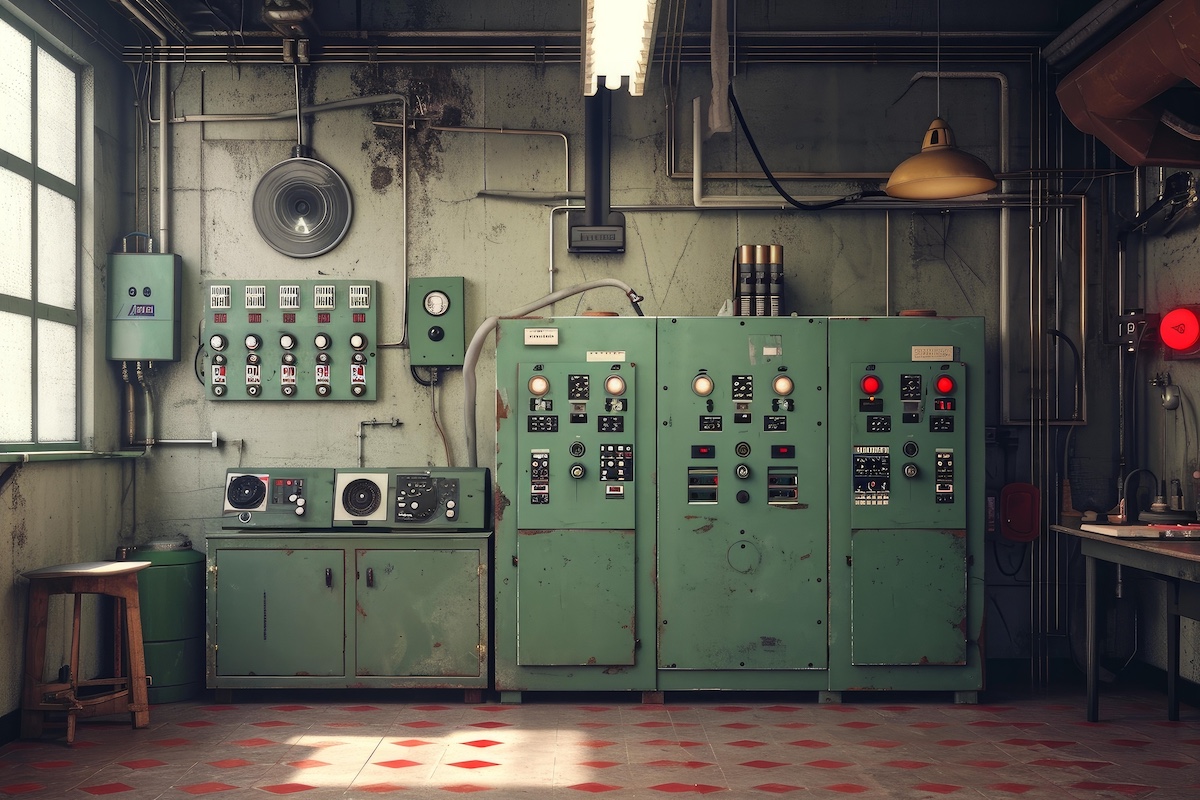

In modern industrial environments, uptime is everything. Whether operating food manufacturing lines, cold storage facilities, process engineering systems or automated logistics operations, the ability to keep equipment running reliably is a direct determinant of profitability and compliance. A single component failure in a control panel, PLC, refrigeration plant or power distribution system can halt production, cause product loss or create safety risks. Yet many facilities still carry limited spares, hold obsolete stock, or rely on reactive purchasing when faults occur.

Developing a structured critical spares strategy transforms this situation. It allows businesses to prevent extended downtime by ensuring that essential components are available when needed. A well-designed strategy is not simply about keeping parts in a cupboard. It is a systematic approach that assesses risk, evaluates lead times, reviews equipment criticality, and aligns spare stock with real-world engineering needs. Introducing criticality analysis and criticality assessment is essential for identifying which spares are most vital to operational continuity, as these processes evaluate and prioritise assets and spare parts based on their impact on production, downtime, safety, and lead times.

This guide explains how industrial facilities can create a robust critical spares strategy using engineering principles, compliance requirements, risk analysis and lifecycle planning. Critical spares management is a key part of spares management, focusing on minimising downtime, supporting asset performance, and ensuring supply chain resilience. It is based on JBB Electrical’s extensive field experience supporting uptime-critical industrial operations.

💡 Key Insight:

A critical spares strategy is not a stocklist. It is a core part of your risk management model and a direct contributor to uptime, safety, compliance, and improved asset performance, supporting overall operational effectiveness.

Why Critical Spares Are Important

When a key electrical or automation component fails, production often stops instantly. Equipment failure can lead to costly downtime and significant equipment downtime, with the duration determined not just by the fault itself but by how quickly engineers can source and replace the part.

Without critical spares, facilities face:

extended production downtime

the risk of equipment failure leading to costly downtime

lost batches or stock loss

compliance breaches (e.g., temperature-critical storage)

inability to restart machinery safely

delayed maintenance and higher repair costs

increased reliance on emergency call-outs

In cold storage environments, a missing spare can mean tens or hundreds of thousands of pounds of stock loss. In automated production lines, a single failed PLC module can shut down an entire line. In food manufacturing, downtime can affect product safety and audit outcomes.

The True Cost of Not Holding Critical Spares

Many businesses underestimate the cost of downtime because the impact goes beyond direct lost output. When a key component is unavailable, other hidden costs accumulate rapidly.

These can include:

expedited shipping or emergency procurement costs

engineer overtime and callout fees

production rescheduling

increased wear on remaining machinery

inability to fulfil customer orders

lost product due to uncontrolled temperature

wasted raw materials or partially completed batches

⚠ Critical Warning:

A single missing part can cause a long shutdown. In high-volume facilities, even one hour of downtime can cost more than the price of a full spare parts inventory. Businesses must carefully weigh inventory costs—such as holding expenses, overstocking, and obsolescence—against the potential losses from not having critical spares available.

What Counts as a Critical Spare?

Critical spares are components that, if they fail, would cause immediate or rapid downtime, safety issues or compliance breaches. They are often essential items that cannot be sourced quickly during breakdowns due to lead times, availability or supplier constraints. In a critical spares strategy, critical items and high risk parts are prioritized based on their impact on production and safety.

Examples include:

PLC modules (CPU, I/O cards, communication modules)

power supplies

contactors, overloads and relays

safety relays and safety circuit components

HMI screens

VSDs or variable speed drives

temperature sensors and probes

evaporator fan motors (for cold stores)

control transformers

fuses and MCBs of specific types

Identifying critical parts is essential for operational continuity, as these parts have a significant impact on minimising downtime and supporting proactive maintenance.

The exact list varies by site, depending on equipment type, production demands, service-level agreements, and compliance risks.

Engineering Factors That Influence Critical Spares Requirements

Developing a robust spares strategy requires understanding how different engineering systems behave and how failures propagate. Failure prevention is a key goal of understanding these engineering factors, as it helps organisations proactively avoid equipment breakdowns and improve reliability. The following factors significantly affect spare requirements.

1. Component Lead Time

Some PLC modules or VSD models have lead times ranging from several days to several months—especially when discontinued or on manufacturer allocation cycles. Long lead times can disrupt production schedules and cause extended downtime, making it essential to align your critical spares strategy with production planning.

2. Equipment Criticality

Equipment that forms part of a continuous process or temperature-critical environment needs higher availability of spares.

Equipment criticality is often assessed based on how essential the equipment is to the core production process, as the unavailability of critical parts can halt operations and significantly impact productivity and safety.

3. Frequency of Failure

Components with known wear patterns (e.g., contactors, fan motors, PSU units) should be stocked.

Analysing the frequency of failure for these components supports failure prevention strategies by enabling proactive maintenance and ensuring the necessary spares are available when needed.

4. Compliance and Audit Requirements

Food, pharmaceutical and cold chain sectors require rapid restoration of temperature or batch control systems.

5. Age of Equipment

Older systems may require more spares due to obsolescence, higher failure rates and limited manufacturer support.

📊 Industry Statistic:

A lot of industrial downtime related to control panels involves components that were already at end-of-life or difficult to source at the time of failure.

Why Many Businesses Fail to Hold the Right Spares

Despite the importance of critical spares, many facilities hold incomplete, outdated or unsuitable spares inventories. Common issues include:

holding incorrect part numbers or incompatible versions

keeping obsolete parts for systems no longer in service

no lifecycle planning for PLC or drive components

poor labelling or storage conditions that damage parts

lack of engineering involvement in purchasing decisions

over-reliance on suppliers during emergency breakdowns

Maintaining accurate and up-to-date master data is essential for effective spare parts management. High-quality master data helps prevent issues such as holding obsolete or incorrect parts, and supports proper categorisation and inventory optimisation.

❌ Common Mistake:

Many facilities assume that a general parts supplier will always have critical automation components in stock. This is rarely the case, especially for PLC hardware.

How to Develop a Critical Spares Strategy

A critical spares strategy follows a structured process based on engineering risk assessment, asset condition surveys, supplier analysis, and operational requirements. Conducting a thorough criticality analysis and criticality assessment is essential for prioritising spares, as it helps identify which components have the greatest impact on equipment performance, operational risks, and maintenance planning. The following method provides a practical approach used by JBB Electrical across industrial facilities.

Step 1: Identify Critical Equipment

Start by listing all assets whose failure would halt production, compromise compliance or create safety risks. This includes:

control panels

PLCs and I/O modules

refrigeration plant

processing lines

conveyor systems

HVAC and environmental control systems

Step 2: Analyse Component-Level Risk

For each asset, identify which components are most critical. This requires understanding how the equipment operates, failure modes and their effects.

This analysis helps identify high-risk parts—critical spares that are vital for equipment maintenance and repair—by prioritising components based on failure history, reliability data, and risk profile to ensure operational continuity.

Step 3: Assess Availability and Lead Time

Next, research lead times. Components with long lead times, supply chain volatility or end-of-life status should be prioritised.

Step 4: Review Failure Frequency and Maintenance Records

Analyse historical maintenance data, engineer reports and downtime logs to identify recurring failures.

By analysing historical data from maintenance records, you can better predict future spare parts needs and prevent shortages.

Step 5: Evaluate Compatibility and Obsolescence

Check whether the parts you plan to stock are compatible with current equipment versions. PLC platforms, firmware versions and VSD models frequently change.

Step 6: Determine Spare Holding Quantities

Based on risk, lead time and equipment criticality, assign holding levels such as:

1–2 critical spares for essential components

stock rotation for wear items (contactors, overloads)

seasonal backups for refrigeration or HVAC

Maintaining an appropriate level of safety stock for critical components is essential to prevent production downtime, ensure safety, and maintain operational continuity, especially for parts that directly impact health and safety concerns.

Step 7: Document and Integrate the Strategy

Compile the full spares strategy into a centralised document and integrate it with procurement systems and preventive maintenance schedules. Integrating the strategy with enterprise asset management systems can automate inventory tracking and improve maintenance planning.

ℹ Engineering Note:

A critical spares strategy should be treated as part of your preventive maintenance programme, not an isolated purchasing exercise.

Inventory Control and Accuracy

Accurate inventory control is the backbone of successful spare parts management. Without precise tracking of inventory levels and usage, organizations risk stockouts that can halt production or overstocking that ties up excess capital and storage space. Implementing a robust inventory management system—such as an Enterprise Asset Management (EAM) platform—enables maintenance teams to monitor critical spare parts in real time, streamline inventory control processes, and enhance inventory accuracy.

Leveraging predictive analytics and automation further optimises inventory management by forecasting demand, identifying consumption trends, and ensuring that critical spare parts are always available when needed. This data-driven approach helps minimise downtime, reduce unnecessary holding costs, and support maintenance teams in making informed decisions. By maintaining accurate inventory records and regularly reviewing inventory data, organisations can achieve greater operational efficiency and ensure that their spare parts management strategy remains effective.

Supply Chain Management

A resilient supply chain is essential for ensuring the timely availability of critical spare parts. Effective supply chain management involves building strong relationships with multiple suppliers, negotiating favourable terms, and closely monitoring lead times to avoid disruptions. By diversifying their supplier base and adopting a multi-sourcing strategy, organisations can reduce their vulnerability to supply chain disruptions and maintain a steady flow of essential parts.

Regularly reviewing supplier contracts and evaluating supplier performance are key practices in optimising supply chain operations. This proactive approach helps organisations anticipate potential delays, adjust procurement strategies, and ensure that critical spare parts are delivered on schedule.

What Should Be Included in a Critical Spares Strategy?

A comprehensive strategy includes technical specifications, supplier information, engineering priorities and lifecycle forecasts.

Your strategy document should include:

approved part numbers

component descriptions and versions

manufacturer and supplier details

current lead times

recommended holding levels

storage requirements

replacement intervals

lifecycle status (active, discontinued, last-time buy)

standard operating procedures for parts receiving, issuance, and returns

Why PLC and Control Panel Spares Are High Priority

PLC failures cause immediate downtime across entire production systems. Control panel components such as power supplies, relays, contactors and I/O modules are high-risk, high-impact spares.

Holding these items prevents:

line stoppages

safety system activation

loss of SCADA visibility

extended troubleshooting time

❗ Critical Spares Priority:

If your facility relies heavily on PLCs, you should hold CPU modules, I/O cards and communication modules on site. These are often unavailable during emergency breakdowns.

Spare Storage, Testing and Rotation

Critical spares are only useful if stored correctly and kept in working condition. Poor storage can damage electronics, degrade seals or affect mechanical components.

Best practices include:

temperature-controlled storage

anti-static protection for PLC components

clear shelving and labelling

regular testing of electrical components

rotation of wear parts to prevent ageing

It is important to note that some spare parts, especially used or remanufactured ones, may have a limited lifespan and should be monitored closely.

Integrating Critical Spares into Preventive Maintenance

A critical spares strategy works best when integrated with preventive maintenance. Engineers should identify parts that show wear during inspections and ensure matching spares exist. Predictive maintenance can further enhance this process by using data-driven insights to identify which parts are most likely to fail, allowing for more effective stocking parts decisions.

Examples include:

contactors showing early wear

PSUs running hot on thermal imaging

evaporator fan motors making noise

aged PLC cards with intermittent faults

Stocking parts that predictive maintenance identifies as likely to fail is essential to minimise downtime and maintain operational efficiency.

Training and Collaboration

Continuous training and effective collaboration are vital components of a successful spare parts management program. Providing maintenance teams with regular training on best practices in inventory control, maintenance planning, and spare parts management ensures that they have the knowledge and skills needed to optimize equipment performance and reduce errors. Well-trained teams are better equipped to identify critical spares, manage inventory efficiently, and respond quickly to maintenance needs.

Collaboration between maintenance, procurement, and operations departments further strengthens spare parts management by ensuring that all stakeholders are aligned on sourcing, storing, and utilizing spare parts. By fostering open communication and a culture of continuous improvement, organizations can streamline maintenance activities, enhance operational efficiency, and ensure that critical spare parts are always available when required.

JBB’s Engineering-Led Approach to Critical Spares

JBB Electrical applies a structured methodology for developing and maintaining critical spares strategies. This methodology aligns with the JBB lifecycle model: Assess → Modernise → Protect → Prevent → Support.

📋 JBB Critical Spares Framework

Assess – Identify essential components and analyse failure risks to determine what must be held in stock.

Modernise – Update spares inventories to align with current equipment, upgraded systems, and manufacturer requirements.

Protect – Secure availability with controlled storage, environmental safeguards, and proper handling procedures.

Preventing – Minimise downtime by ensuring high-risk and long-lead items are always ready for immediate use.

Support – Provide ongoing review, optimisation, and technical guidance to keep the spares framework effective and aligned with operational needs.

FAQs

What risks does this issue create?

Lack of critical spares increases downtime risk, causes production loss, generates compliance issues and creates operational vulnerability. It also drives up maintenance costs through emergency procurement.

How does compliance affect this?

Facilities within food, pharmaceutical and cold chain sectors must protect product integrity. Missing spares can delay restoration of critical systems, risking audit failure or stock loss.

What preventive measures should be taken?

Implementing a structured critical spares strategy, reviewing lifecycle status, integrating with preventive maintenance and maintaining proper storage all reduce risk.

How do modern systems improve reliability?

Modern PLCs, VSDs and control components have better diagnostics, improved communication and enhanced stability. Holding compatible spares ensures quick recovery from failures.

Next Step: Request a Compliance & Breakdown Prevention Assessment

A critical spares strategy is essential for maintaining uptime in industrial environments. JBB Electrical’s Compliance & Breakdown Prevention Assessment identifies risks, evaluates equipment condition, reviews control panels, checks PLC hardware and provides a clear roadmap for developing a tailored critical spares strategy.

Request a Compliance & Breakdown Prevention Assessment today to protect uptime and ensure your facility is prepared for unexpected breakdowns.